Understanding the Advantages of Acb Circuit Breaker in Modern Electrical Systems

In today's rapidly evolving electrical landscape, the significance of reliable and efficient protection systems cannot be overstated. Among the various protective devices available, the ACB Circuit Breaker stands out due to its unique advantages in enhancing safety and operational efficiency in modern electrical systems. Industry expert John Smith, a leading electrical engineer with over two decades of experience, emphasizes, "The ACB Circuit Breaker not only safeguards equipment but also optimizes power distribution, making it essential for contemporary applications."

The adaptability of ACB Circuit Breakers in handling high current loads and their capability to provide various operational features make them indispensable in industrial and commercial settings. As businesses increasingly demand smarter solutions to manage their electrical infrastructure, understanding the functionality and benefits of ACBs becomes crucial.

This article will explore the unique advantages offered by ACB Circuit Breakers and how they contribute to the resilience and efficiency of modern electrical networks. By leveraging insights from industry specialists, we aim to illuminate the critical role that ACB Circuit Breakers play in safeguarding electrical systems while ensuring seamless operation.

Importance of Circuit Protection in Modern Electrical Systems

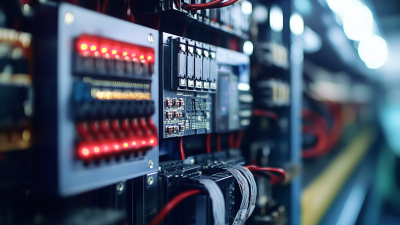

In today's rapidly advancing electrical systems, the importance of circuit protection cannot be overstated. As electrical demands increase, safeguarding these systems becomes a priority to prevent malfunctions, equipment damage, and fire hazards. Circuit breakers, particularly advanced concepts like ACB (Air Circuit Breakers), play a crucial role in managing electrical flow, ensuring safety, and enhancing reliability.

ACBs effectively detect anomalies in electrical currents, such as overloads or short circuits, and respond by interrupting the flow of electricity. This immediate reaction is vital for protecting not only the electrical systems but also the devices connected to them. By incorporating ACBs, modern electrical systems can maintain operational efficiency while minimizing the risks associated with electrical failures. Thus, the integration of effective circuit protection mechanisms is essential for optimal performance and safety in our increasingly electrified environments.

Understanding the Working Principle of ACB Circuit Breakers

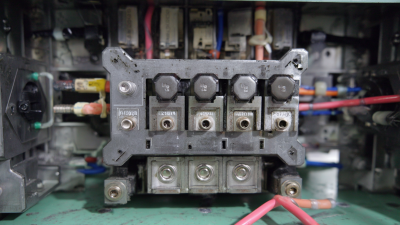

Air Circuit Breakers (ACBs)

are pivotal components in modern electrical systems, designed to protect electrical circuits from overloads and faults. Understanding their working principle is crucial for engineers and technicians alike. ACBs function by automatically interrupting the flow of electricity when a fault condition is detected. This interruption is achieved through several mechanisms, including thermal and electromagnetic trip units, which respond to excess current by tripping the circuit. The design of ACBs allows for quick response times, minimizing potential damage to electrical systems and enhancing safety.

Tips: When selecting an ACB, consider the specific parameters of your electrical system, such as the voltage and current ratings. It's also vital to assess the environmental conditions where the ACB will be installed, as factors like humidity and temperature can affect performance. Regular maintenance checks are essential to ensure the reliability of ACBs in your installations.

The market for ACBs is projected to grow significantly, driven by increasing power demands due to urbanization and a resurgence in manufacturing activity. With forecasts indicating a rise in market size from $3.24 billion in 2019 to $7.17 billion by 2032, it's clear that ACBs will play a crucial role in bolstering electrical infrastructure globally. As industries adapt to these demands, the importance of reliable circuit protection mechanisms becomes ever more apparent.

Key Advantages of ACB Circuit Breakers Over Traditional Breakers

Air Circuit Breakers (ACB) present several significant advantages over traditional circuit breakers, making them an ideal choice for modern electrical systems. One of the key benefits of ACBs is their ability to handle high current loads efficiently. Unlike traditional breakers, which may struggle with heavy electrical demands, ACBs can effectively interrupt short circuits and overloads, ensuring better protection for electrical systems and equipment. This capability is crucial in industrial and commercial settings where electrical loads are unpredictable and can change rapidly.

Another advantage of ACBs is their improved operational lifespan and maintenance requirements. Traditional circuit breakers often require frequent checks and replacements due to wear and tear, especially under high load conditions. In contrast, ACBs are designed with robust components that can withstand frequent operations without degrading performance. Additionally, many ACBs come equipped with advanced monitoring and protection features, allowing for real-time diagnostics and reduced downtime. This means that facilities can significantly lower maintenance costs and enhance the reliability of their electrical infrastructure, making ACBs a preferred choice in today's dynamic energy landscape.

Factors to Consider When Integrating ACBs into Electrical Systems

When integrating Air Circuit Breakers (ACBs) into modern electrical systems, several critical factors must be considered to maximize their effectiveness. First, the selection of appropriate ACB types based on application requirements is vital. This choice can impact system performance, reliability, and safety. Modern electrical systems often demand devices that can handle high voltage and current ratings while providing protection against overloads and short circuits. Thus, ensuring that the ACBs align with specific operational needs is essential for enhancing system efficiency.

Furthermore, the coordination between ACBs and other protection devices is crucial for seamless operation. The integration process must consider the potential for coordination issues among various components in the electrical system. Effective settings and configurations will facilitate instantaneous protection and minimize downtime during faults.

Additionally, the physical installation site and environmental conditions, such as temperature and humidity, should be assessed to determine the suitability of ACBs. By addressing these factors, engineers can ensure that ACBs function optimally within the electrical infrastructure, contributing to a more resilient and reliable system.

Best Practices for Maintenance and Operation of ACB Circuit Breakers

Maintaining and operating Air Circuit Breakers (ACB) effectively is crucial for ensuring reliability in modern electrical systems. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of electrical failures are attributed to inadequate maintenance practices. Regular inspection and testing of ACBs can enhance their longevity and performance, reducing the likelihood of unexpected outages. Best practices include visual inspections for physical damage, ensuring that contact points are clean and free from debris, and verifying the integrity of insulation.

Moreover, executing periodic functional tests helps to confirm that ACBs respond appropriately under fault conditions. A study published in the IEEE Transactions on Industry Applications indicates that proactive maintenance can lower operational costs by up to 25%, emphasizing the financial advantages of diligent upkeep. Additionally, training operational staff on the importance of ACB diagnostics and advancements in technology can further optimize their performance. Keeping abreast of manufacturer guidelines and incorporating the latest monitoring systems are essential steps in maximizing the efficiency and safety of electrical systems employing ACBs.

Related Posts

-

Unlocking Energy Efficiency: The Advantages of Air Circuit Breakers for Global Industries

-

Top 10 Electronic Circuit Breaker Manufacturers from China at the 137th Canton Fair

-

Revolutionizing Protection Standards for Low Voltage Circuit Breakers in 2030

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

-

5 Key Reasons Why the Best Electric Main Breaker is Essential for Your Energy Efficiency

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500