Why You Should Choose an Air Circuit Breaker Factory for Reliable Power Protection

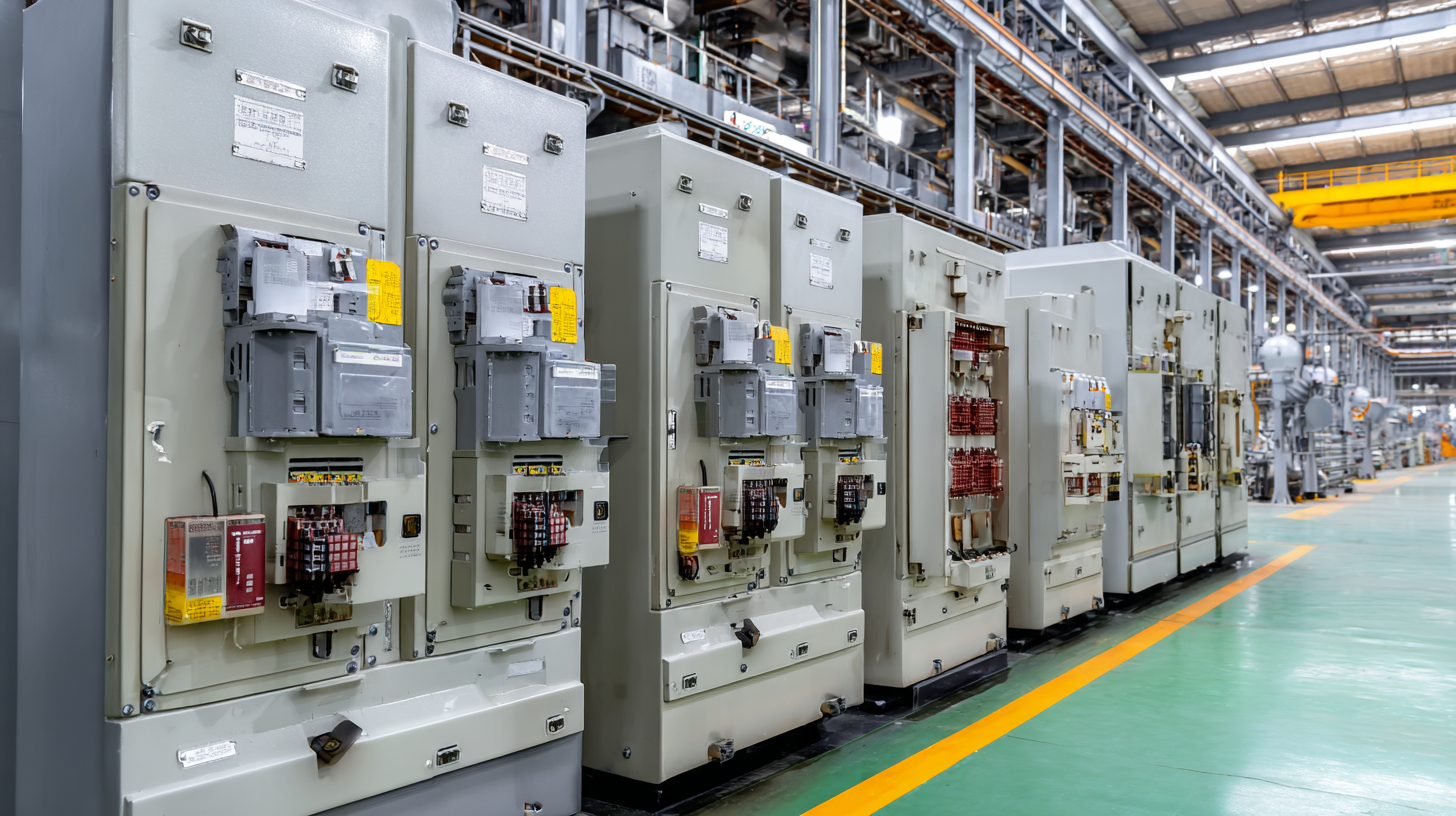

In today's rapidly evolving electrical landscape, ensuring the safety and reliability of power distribution systems is paramount. Choosing the right components is critical, and one of the most vital choices you can make is selecting an Air Circuit Breaker Factory. An air circuit breaker (ACB) is designed to protect electrical circuits from overload and short circuits, making it an essential element in industrial and commercial applications. However, not all ACBs are created equal; the factory where they are manufactured plays a significant role in their performance and dependability.

In this article, we will explore the top 10 reasons for opting for a reputable Air Circuit Breaker Factory when seeking reliable power protection solutions. From superior manufacturing processes to rigorous quality control measures, details of how an esteemed factory can enhance the longevity and effectiveness of circuit breakers will be discussed. Ultimately, we aim to equip readers with insights that underline the importance of factory selection in safeguarding electrical systems, ensuring both operational efficiency and safety in power protection strategies.

Benefits of Partnering with a Reputable Air Circuit Breaker Factory

Collaborating with a reputable air circuit breaker factory brings numerous advantages that can significantly enhance the reliability of your power protection needs. A well-established manufacturer not only offers high-quality products but also provides technical support and insights gained from years of experience in the industry. By partnering with such a factory, you gain access to cutting-edge technology and innovations that can optimize your electrical systems, ensuring efficient performance and safety.

Moreover, a trusted factory typically has rigorous quality control measures in place, guaranteeing that each air circuit breaker meets or exceeds industry standards. This commitment to quality translates into fewer failures, reduced maintenance costs, and overall enhanced safety for your electrical installations. Additionally, they often provide valuable training and resources, empowering your team to make informed decisions about power protection solutions. By selecting a reputable air circuit breaker factory, you invest in a partnership that promotes long-term reliability and success in your operations.

Key Features to Look for in Air Circuit Breakers for Power Protection

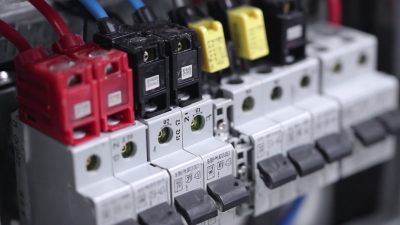

When selecting an air circuit breaker (ACB) for reliable power protection, it is crucial to consider key features that ensure optimal performance and safety. According to the International Electrotechnical Commission (IEC), ACBs are essential for protecting electrical circuits against overloads and short circuits, which can lead to equipment failure and pose fire hazards. Modern ACBs are engineered with advanced thermal and magnetic trip settings, allowing for precise response to electrical faults. Reports indicate that ACBs equipped with digital monitoring features can enhance system reliability by providing real-time data on circuit performance, contributing to reduced downtime and maintenance costs.

Another critical aspect to examine is the breaking capacity of the ACB. The breaking capacity indicates the maximum fault current that the device can interrupt without causing damage. The Global Data Report suggests that the demand for high breaking capacity ACBs is on the rise, especially in industries with fluctuating load demands, such as manufacturing and energy production. Additionally, ACBs that have a modular design offer flexibility for future expansions or upgrades, ensuring long-term reliability and adaptability to changing electrical environments. By choosing an ACB factory that prioritizes these features, businesses can significantly enhance their power protection strategy.

Steps to Evaluate the Reliability of an Air Circuit Breaker Manufacturer

When evaluating the reliability of an air circuit breaker manufacturer, it is crucial to consider their commitment to green design and resource utilization. A manufacturer focused on sustainability not only enhances the electrical life of their products but also ensures that the circuit breakers are designed for long-term performance. This is essential since a qualified circuit breaker maintains its electrical life from the moment it leaves the factory, which is a strong indicator of its reliability during operations.

Additionally, prospective buyers should scrutinize the manufacturer's testing protocols and certifications. Reliable manufacturers typically conduct rigorous testing to verify that their circuit breakers meet industry standards for performance and safety. These tests should reflect the ability of the circuit breakers to function effectively under various conditions, thereby ensuring consistent power protection. By taking these steps, buyers can make informed decisions and select an air circuit breaker factory that prioritizes both durability and environmental responsibility.

Understanding Certifications and Standards for Air Circuit Breakers

When selecting an air circuit breaker manufacturer, understanding the certifications and standards relevant to their products is crucial for ensuring reliable power protection. Air circuit breakers, designed to provide effective interruption and protection from overcurrent and short circuits, must comply with stringent industry standards. Certifications such as IEC 60947-2 and UL 489 outline performance and safety criteria, guaranteeing that the breakers can withstand operational demands while minimizing risks.

Moreover, choosing a factory with recognized certifications not only signifies adherence to quality control processes but also reflects a commitment to continuous improvement. Factories that meet standards from organizations like ISO demonstrate excellence in manufacturing practices. Certified products ensure that customers receive reliable performance and durability, which are essential in minimizing downtime and maintaining efficient power management systems. By focusing on manufacturers with established credentials, businesses can invest in air circuit breakers that are engineered with both safety and functionality in mind.

How to Maintain and Maximize the Lifespan of Your Air Circuit Breakers

To ensure the longevity and reliability of your air circuit breakers, proper maintenance is essential. Regular inspections should be conducted to check for any signs of wear or corrosion. Ensuring that the contact surfaces are clean will help maintain optimal electrical conductivity and performance. Additionally, verify that all connections are secure to prevent overheating, which can lead to premature failure.

Tips:

1. Schedule monthly visual inspections to detect potential issues early.

2. Keep the breaker panel clean and free from dust and debris, which can obstruct airflow and cause overheating.

Another important aspect of maintaining air circuit breakers is to regularly test their functionality. This involves performing routine operational checks and calibration to make sure they trip at the correct levels. By doing so, you ensure that the breakers perform effectively during overload conditions, providing the necessary protection against electrical faults.

Tips:

1. Implement a testing schedule every six months or after significant electrical work.

2. Use advanced testing equipment to accurately measure trip settings and response times.

Related Posts

-

Ultimate Guide to Selecting the Right Air Circuit Breaker for Your Industrial Needs

-

Evaluating Air Circuit Breakers: Key Differences Between Leading Brands in 2023

-

Understanding Thermal Magnetic Circuit Breakers: How They Protect Your Electrical Systems

-

Understanding the Importance of Acb Circuit Breakers in Modern Electrical Systems

-

7 Best Features of Square D MCCB for Optimal Electrical Protection

-

Choosing Reliable Manufacturers: Essential Tips and Solutions for Best China Molded Case Circuit Breakers

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500