How to Choose the Right Low Voltage Circuit Breaker for Your Electrical System Efficiency

In today's fast-evolving electrical landscape, the importance of selecting the appropriate Low Voltage Circuit Breaker (LVCB) cannot be overstated. As the demand for energy-efficient solutions escalates, industry reports indicate that nearly 30% of electrical systems in commercial buildings face inefficiencies largely due to improper circuit protection choices. The right LVCB not only safeguards your electrical infrastructure but also enhances overall system performance and energy efficiency. According to a recent study by the International Electrotechnical Commission, innovative LVCBs can reduce energy loss by up to 15%, leading to significant cost savings over time. Therefore, understanding the key factors in choosing the right LVCB is critical for engineers and facility managers aiming to optimize reliability and efficiency in electrical systems.

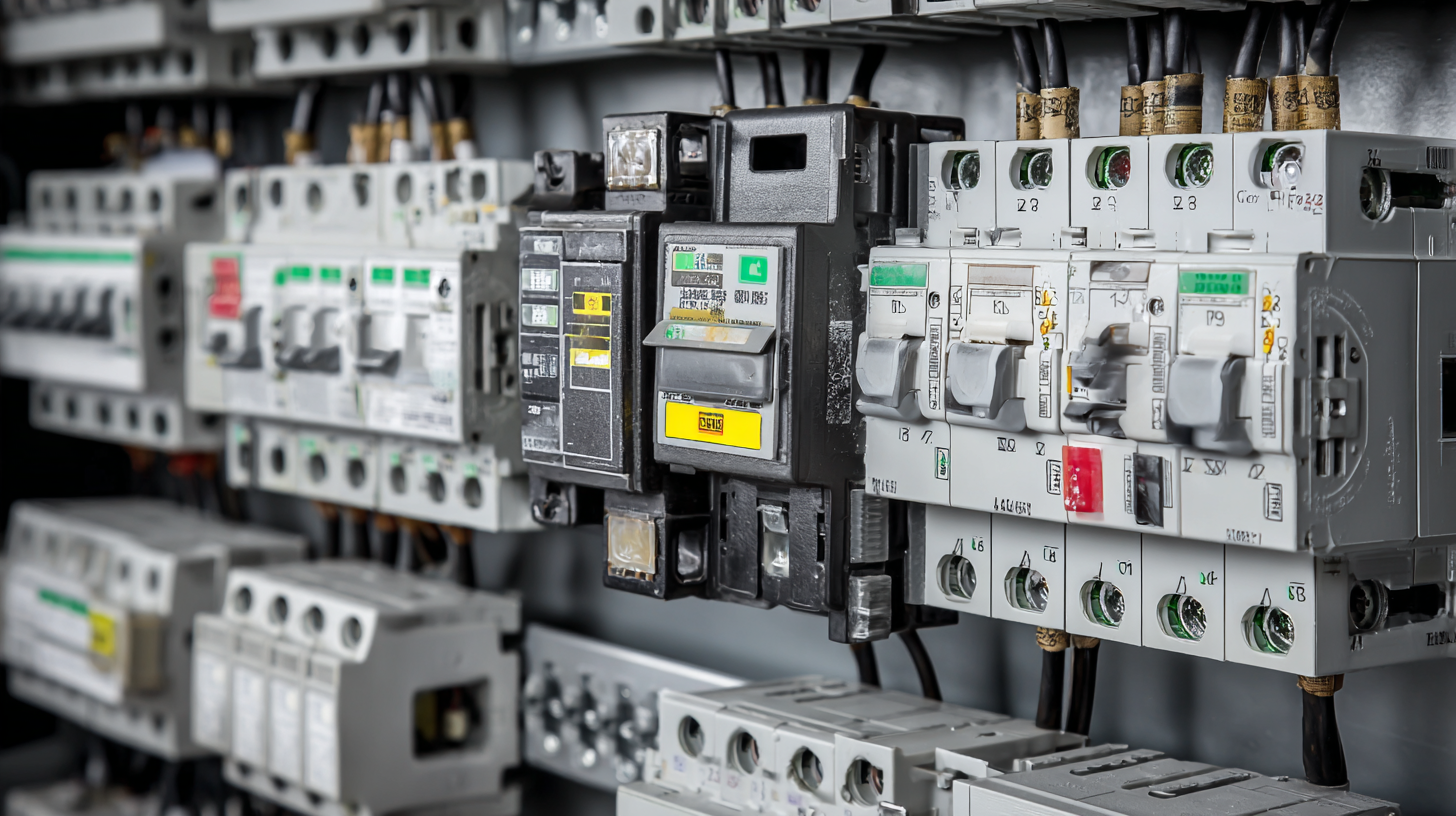

Understanding the Basics of Low Voltage Circuit Breakers for Efficiency

When it comes to improving the efficiency of electrical systems, understanding the basics of low voltage circuit breakers is crucial. Low voltage circuit breakers (LVCBs) are essential for protecting electrical circuits from overloads and short circuits, ensuring both safety and operational reliability. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of electrical failures in industrial settings can be attributed to inadequate circuit protection, highlighting the importance of selecting the right LVCB.

Efficient LVCBs not only prevent system failures but also contribute to energy savings. The U.S. Department of Energy estimates that properly sized and selected circuit breakers can lead to energy efficiency improvements of up to 15%. This is because correctly rated breakers minimize energy loss and reduce the risk of nuisance tripping, allowing systems to operate at optimal levels. By understanding load requirements, the environment, and specific application needs, engineers can select the best LVCBs that enhance overall system efficiency while mitigating risks.

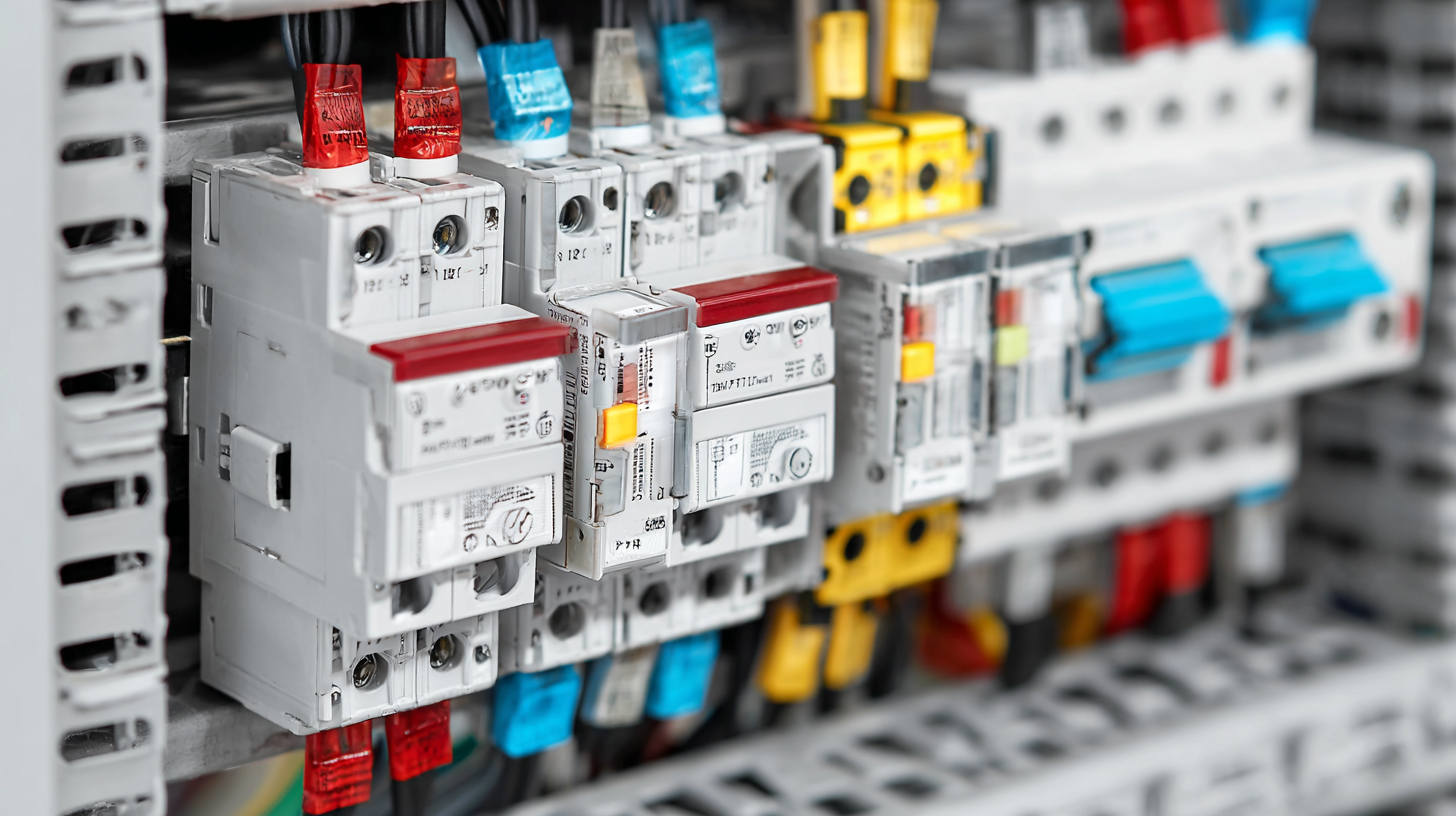

Key Factors to Consider When Selecting Low Voltage Circuit Breakers

When selecting the right low voltage circuit breaker, several key factors must be taken into consideration to ensure optimal efficiency and safety in your electrical system. The first factor is the operational environment. It's essential to assess whether the breaker will be exposed to extreme temperatures, humidity, or dust, as these conditions can significantly affect its performance. For instance, in industrial settings, a breaker with a higher IP rating may be necessary to withstand harsh conditions.

Another important consideration is the load type and the overall electrical system configuration. Different types of loads, such as resistive, inductive, or capacitive, require specific circuit breakers that cater to their unique characteristics. Carefully calculating the expected load and selecting a breaker with adequate interrupting capacity is vital for preventing potential overloads and ensuring the longevity of the electrical system.

Tips: When choosing a circuit breaker, always consult the manufacturer's specifications and consider using a breaker that features a trip unit suitable for your application. Additionally, evaluating the expected fault levels in your system can help you choose a breaker that not only protects your equipment but also ensures compliance with local regulations and standards.

Evaluating the Electrical Load Requirements for Your System

When evaluating the electrical load requirements for your system, identifying the specific needs of your application is crucial. The demand for electricity continues to rise, particularly in sectors like data centers where load growth has significantly increased over the past decade. Understanding the anticipated load can help you select a low voltage circuit breaker that aligns with your system's efficiency and safety requirements.

Tips: Start by conducting a comprehensive assessment of your existing and future load demands. Consider factors such as peak load, continuous loads, and seasonal variations. Implement techniques like machine learning for load forecasting, which can provide insights into expected power needs and enhance your decision-making process.

Incorporating flexible system designs, such as multi-load and multi-source systems, can also improve the resilience of your electrical system. As charging demands for electric vehicles grow, it's essential to ensure that your circuit breakers can handle fluctuations in load without compromising performance. Prioritizing regular performance assessments will ensure that your system remains efficient and responsive to changes in electrical demand.

Assessing Environmental Conditions Impacting Circuit Breaker Performance

When selecting the right low voltage circuit breaker, assessing the environmental conditions that can impact performance is crucial. Factors such as temperature, humidity, and dust can significantly affect a circuit breaker's functionality and reliability. According to a report by the International Electrotechnical Commission (IEC), circuit breakers operating in temperatures exceeding 40°C may experience a 10% reduction in performance efficiency. This stark statistic underscores the importance of environmental assessment before installation.

In addition to temperature, humidity levels play a vital role in the longevity and performance of circuit breakers. For instance, circuit breakers exposed to high humidity are at risk of corrosion and electrical failures. A study conducted by the Institute of Electrical and Electronics Engineers (IEEE) reported that circuit breakers in high-humidity environments can have a failure rate increase of up to 15%. Ensuring that the selected circuit breaker is rated for the specific environmental conditions enhances safety and reliability, preventing costly system interruptions and maintenance. Proper attention to these factors promotes not only the performance of the circuit breaker but also the overall efficiency of the electrical system.

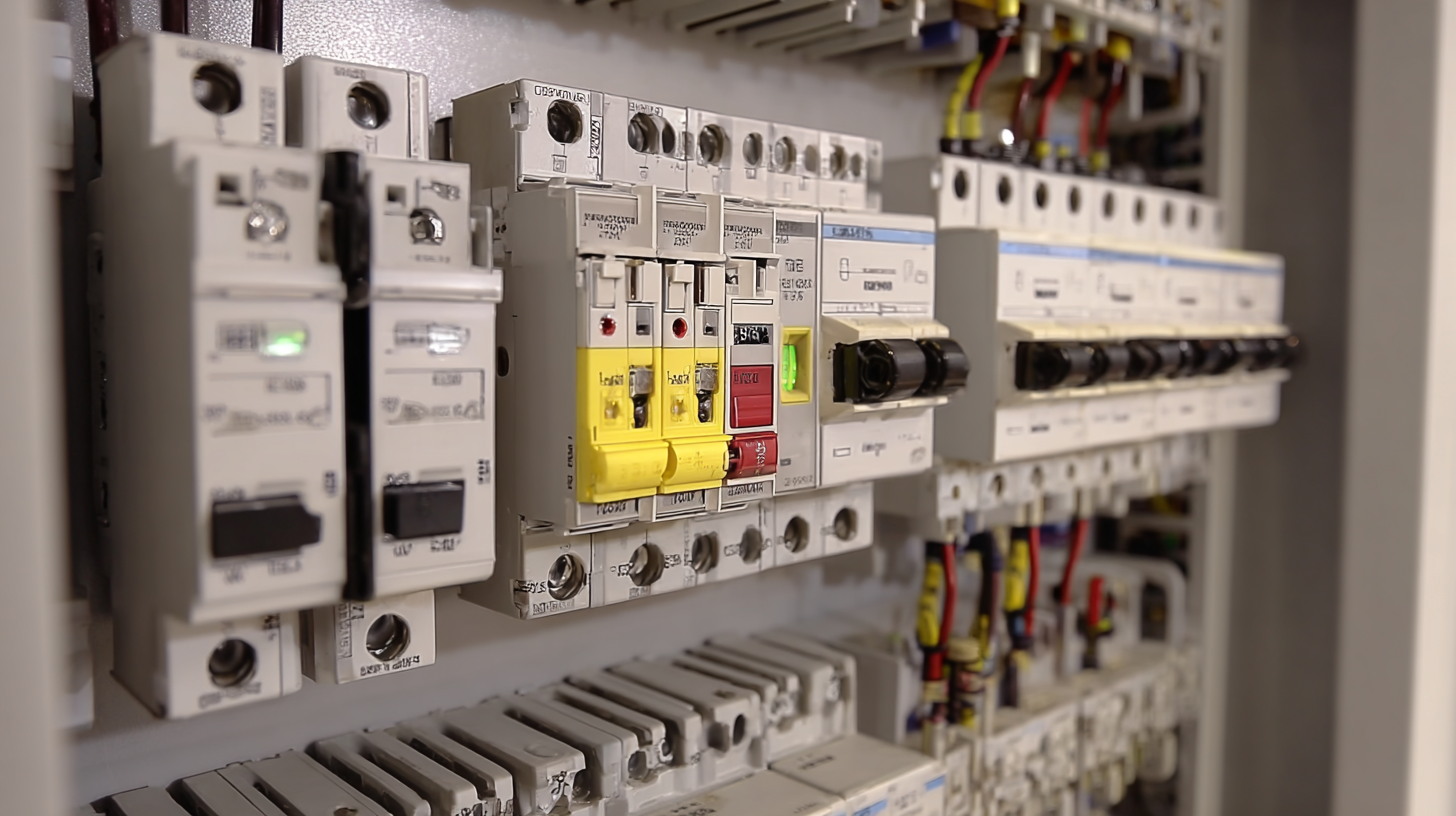

Comparing Different Types of Low Voltage Circuit Breakers for Best Fit

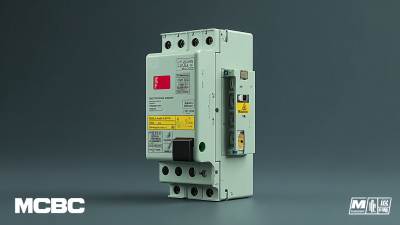

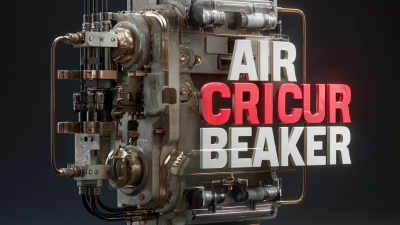

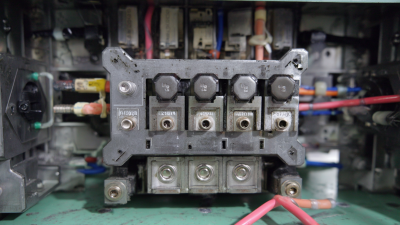

When selecting the right low voltage circuit breaker for your electrical system, it's essential to understand the various types available to ensure maximum efficiency. Low voltage circuit breakers come in several styles, including miniature circuit breakers (MCBs), residual current devices (RCDs), and molded case circuit breakers (MCCBs). Each type serves a unique purpose; for instance, MCBs protect against overloads and short circuits, while RCDs focus on earth faults to prevent electric shock. Assessing your specific requirements will help narrow down the best fit.

In addition to understanding the types, consider the ratings and specifications of the circuit breakers that correspond to your system’s voltage and current needs. Features like breaking capacity and operational characteristics play pivotal roles in determining how well a breaker performs under various conditions. Make sure to compare options based on their quality, reliability, and compatibility with your existing system to make a well-informed decision that enhances your electrical system's efficiency.

How to Choose the Right Low Voltage Circuit Breaker for Your Electrical System Efficiency

| Circuit Breaker Type | Current Rating (A) | Voltage Rating (V) | Number of Poles | Tripping Curve | Applications |

|---|---|---|---|---|---|

| Miniature Circuit Breaker (MCB) | 6 - 63 | 230/400 | 1, 2, 3, 4 | B, C, D | Lighting and Small Power Circuits |

| Residual Current Circuit Breaker (RCCB) | 30, 100, 300 | 230/400 | 2, 4 | N/A | Protection Against Earth Leakage |

| Earth Leakage Circuit Breaker (ELCB) | 15 - 100 | 230 | 2, 3, 4 | N/A | Sensitive Earth Fault Protection |

| Molded Case Circuit Breaker (MCCB) | 50 - 2500 | 400 | 3, 4 | B, C, D | Industrial and Commercial Applications |

| Air Circuit Breaker (ACB) | 800 - 6000 | 400 | 3, 4 | B, C, D | Power Distribution Systems |

Related Posts

-

Ultimate Checklist for Choosing the Best Low Voltage Circuit Breaker

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

-

The Future of Innovative Energy Management with Best Air Circuit Breakers

-

Revolutionizing Protection Standards for Low Voltage Circuit Breakers in 2030

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500