How to Choose the Right China Molded Case Circuit Breaker?

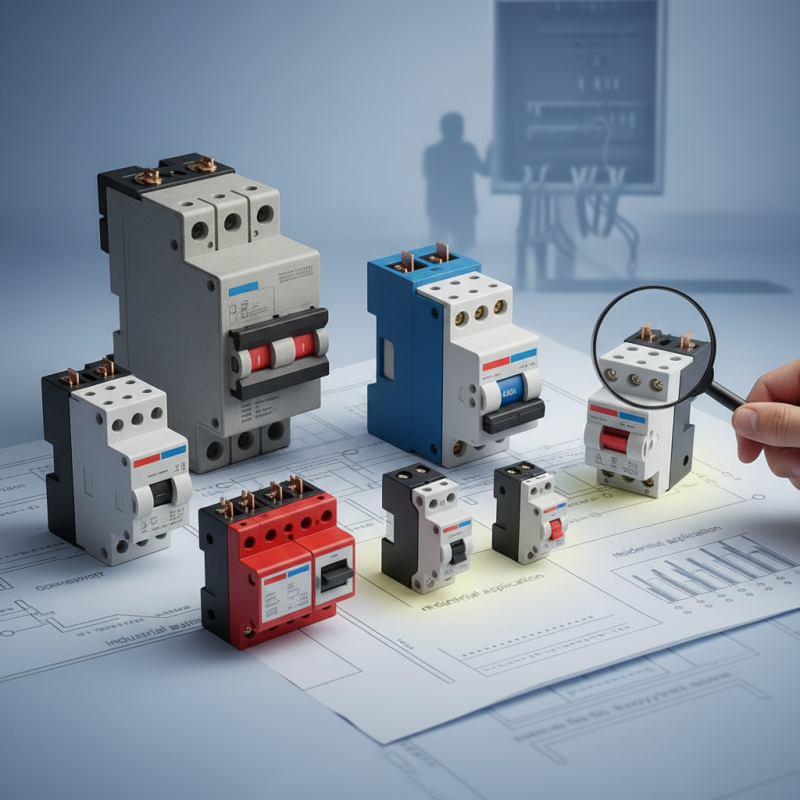

Choosing the right China Molded Case Circuit Breaker is crucial for electrical safety. These devices protect electrical circuits from overloads and short circuits. They come in various sizes and ratings, making selection challenging.

When selecting a China Molded Case Circuit Breaker, consider application type. Industrial and residential needs differ significantly. Ensure compatibility with existing systems to avoid future issues. Inspecting technical specifications is essential. Ratings, trip characteristics, and breaking capacity should align with your requirements.

Often, the choice is not straightforward. Users may overlook complexities. A wrong selection can lead to failures or hazards. Seek expert advice if uncertain. Take time to explore options and understand features. This decision impacts both safety and efficiency in the long run.

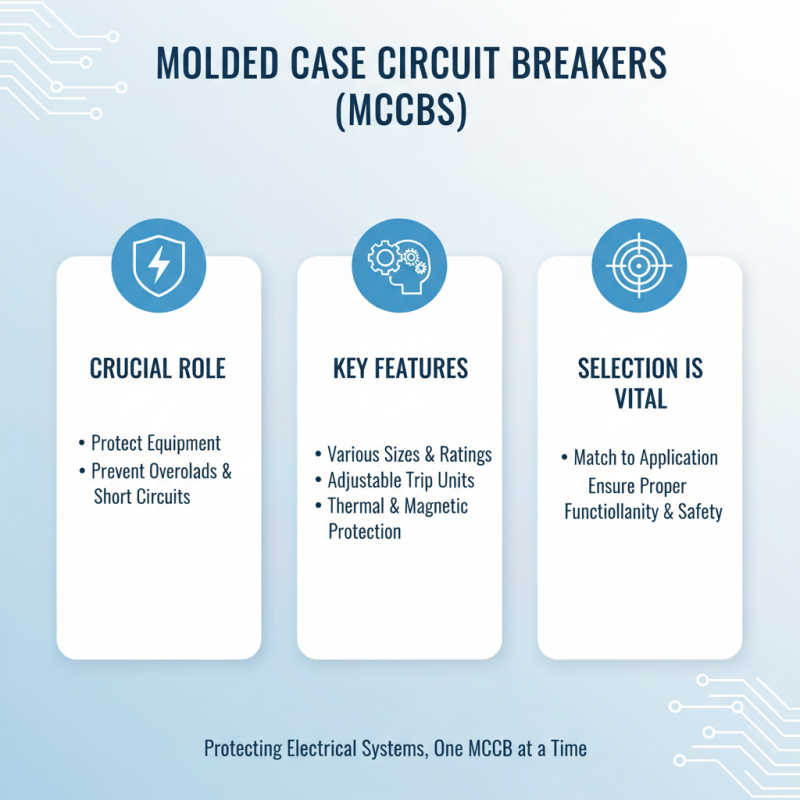

Understanding the Basics of Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) play a crucial role in electrical systems. They protect equipment from overloads and short circuits. Understanding their features is essential for making the right choice. These devices come in various sizes and ratings. It is vital to match them to the specific application they will serve.

When selecting an MCCB, consider its trip settings. These can affect how quickly the breaker responds to faults. Additionally, take note of the current rating. Too low a rating can lead to frequent trips. Conversely, a rating that is too high may fail to protect your equipment properly.

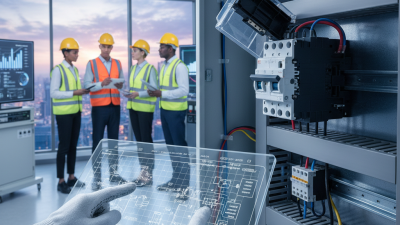

Installation and maintenance are critical as well. Improper installation can lead to malfunction. Regular testing is necessary to ensure functionality. Review any experience with previous breakers. It can highlight areas for improvement or adjustments needed in your selection process. Keep in mind that not every option will meet your needs perfectly. It's a learning journey.

Key Factors to Consider When Choosing a China Molded Case Circuit Breaker

Choosing the right molded case circuit breaker (MCCB) involves several critical factors. First, consider the rated current. MCCBs come in various ratings, usually ranging from 16 A to 2,500 A. About 58% of electrical failures stem from improper sizing of circuit breakers. Selecting the correct amperage is essential to ensure optimal system performance.

Next, evaluate the operating voltage. Most MCCBs support standard voltage levels, typically 230/400 V for residential and light commercial applications. A significant oversight in system design is mismatching voltage ratings, causing equipment failure or safety hazards. According to industry data, over 30% of electrical incidents are linked to voltage incompatibility.

Thermal and magnetic trip settings must also be assessed. Thermal trips protect against prolonged overloads, while magnetic trips guard against short circuits. Many installations overlook the impact of settings, leading to unnecessary outages. Data shows that improper trip settings can lead to failures in up to 40% of installations. Ensure your selection aligns with the specific requirements of your electrical system for enhanced safety and reliability.

Assessing Voltage and Current Ratings for Your Specific Needs

Choosing the right molded case circuit breaker (MCCB) involves understanding voltage and current ratings that align with your specific needs. Different applications have varied requirements. For instance, residential setups might require different specifications compared to industrial uses. Assessing the maximum voltage and current your system will need is crucial. This ensures reliability and safety in operation.

Consider your equipment and its power needs. Devices have rated capacities that can fluctuate with use. Therefore, it’s important to locate the appropriate MCCB that can handle peak currents without tripping unnecessarily. Ignoring these details can lead to inefficiencies or even equipment damage.

Some might overlook the importance of a proper match, thinking any circuit breaker would suffice. This is a risky assumption. If the breaker is under-rated, it may fail to protect your system. If over-rated, it might cause delays during faults. Reflecting on these factors can save significant costs and enhance safety in the long run.

How to Choose the Right China Molded Case Circuit Breaker? - Assessing Voltage and Current Ratings for Your Specific Needs

| Voltage Rating (V) | Current Rating (A) | Usage Scenario | Recommended Application |

|---|---|---|---|

| 230 | 32 | Residential | Home appliances and lighting |

| 400 | 63 | Commercial | HVAC systems and office equipment |

| 690 | 125 | Industrial | Machinery and heavy-duty equipment |

| 1000 | 250 | Large Facilities | Power distribution and substations |

Evaluating Environmental Conditions and Installation Requirements

When selecting a molded case circuit breaker (MCCB), understanding environmental conditions is crucial. Humidity levels play a significant role. High humidity can lead to condensation inside the device. This can cause short circuits. Conversely, dry environments can lead to dust accumulation. Regular maintenance is necessary to ensure optimal performance in challenging conditions.

Temperature is another factor to consider. Extreme heat or cold can affect the breaker’s functionality. Designs may vary based on the operating temperature range. If the unit isn’t rated for the expected climate, it might fail. Users should check insulation ratings closely.

Installation requirements follow closely behind environmental factors. Proper mounting is critical. The surface should be clean and level. This aids in heat dissipation. However, wiring techniques often get overlooked. Inadequate wiring can lead to overheating. It's important to follow installation guidelines meticulously. A small mistake here can have large consequences. Evaluating these elements will help in making informed decisions, which is essential for long-term reliability.

Environmental Conditions Impacting Molded Case Circuit Breaker Selection

Comparing Supplier Quality and Certification Standards in China

When selecting a molded case circuit breaker from China, one critical aspect is supplier quality. Many manufacturers claim high standards, but it is essential to verify these claims. Look for suppliers with established certifications. An ISO 9001 certification can indicate a commitment to quality management. However, this alone does not guarantee that the products will meet your requirements.

Certification standards vary widely among suppliers. Some may have local certifications that are not recognized internationally. This can lead to complications during import or usage. It’s wise to request samples and conduct your tests. Ensure that the breakers meet international safety standards. Be wary of overly cheap options; they might compromise safety for cost.

Communication with potential suppliers is also important. Discuss their manufacturing processes and quality control measures. Don’t hesitate to ask for references from previous clients. This step can provide insight into their reliability. Understanding the supplier’s quality assurance practices can help you make a well-informed decision. These aspects often require careful scrutiny and cannot be rushed. Take the time to reflect on all the factors involved.

Related Posts

-

Top 10 Essential Tips for Choosing Molded Case Circuit Breakers (MCCB)

-

The Evolution of Molded Case Circuit Breakers in a Global Market

-

How to Choose the Right Molded Case Circuit Breaker for Your Electrical Needs

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

How to Choose the Right MCCB Adjustable for Your Electrical Needs

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500