How to Choose the Right Electronic MCCB for Optimal Circuit Protection and Efficiency

In today's rapidly advancing electrical landscape, selecting the right Electronic MCCB (Molded Case Circuit Breaker) is crucial for ensuring optimal circuit protection and operational efficiency. According to a report by MarketsandMarkets, the global MCCB market is projected to grow from USD 6.85 billion in 2021 to USD 9.12 billion by 2026, highlighting the increasing demand for reliable circuit protection solutions. With the rising complexity of electrical systems and the need for enhanced safety measures, understanding the specifications and functionalities of Electronic MCCBs becomes imperative. This guide aims to equip professionals and decision-makers with the knowledge necessary to select the most appropriate MCCB for their unique applications, thereby enhancing performance and safety in electrical installations.

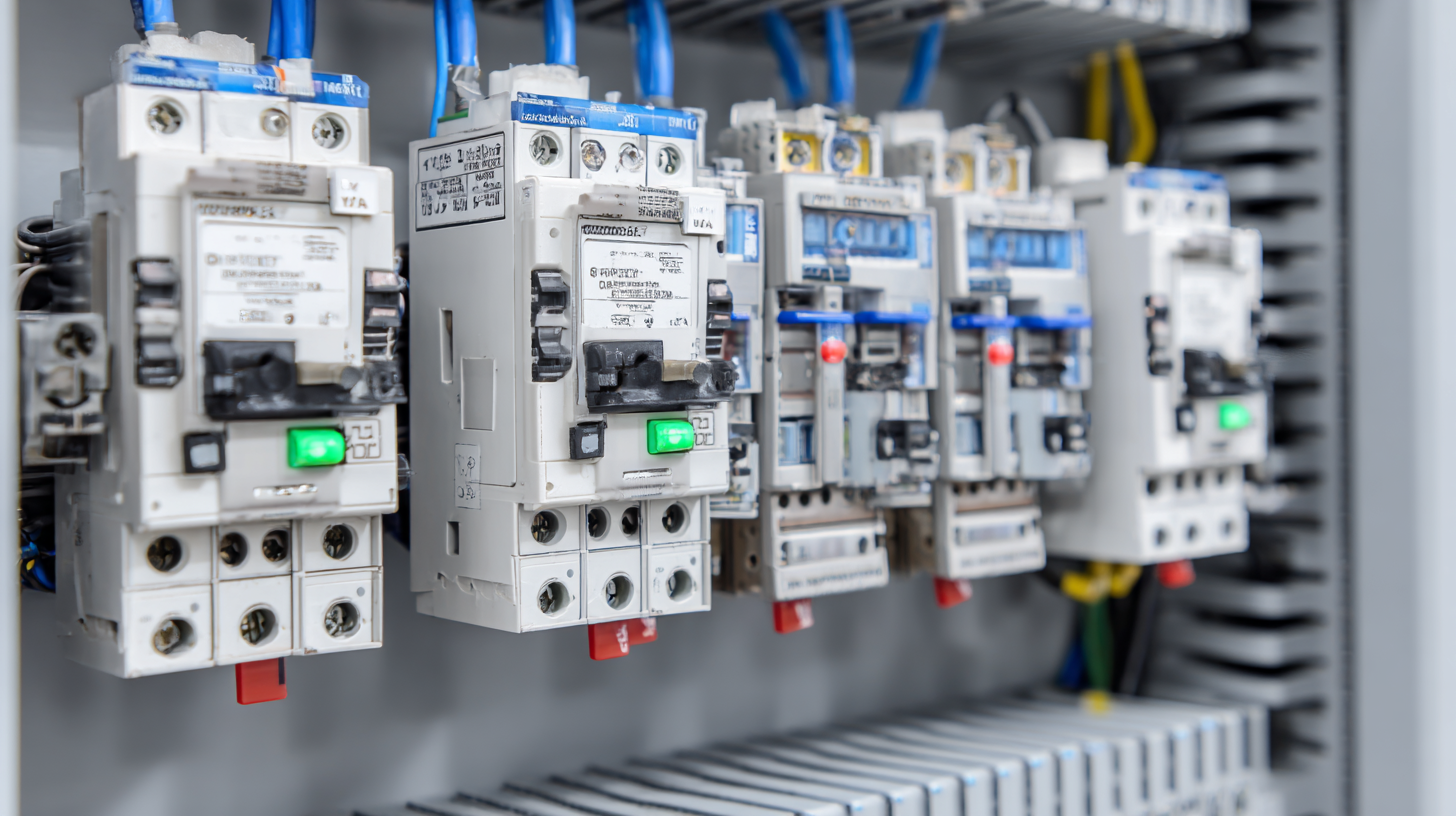

Understanding the Basics of Electronic MCCBs for Circuit Protection

Electronic Miniature Circuit Breakers (MCCBs) have become essential components in modern electrical systems, ensuring not only circuit protection but also enhancing overall efficiency. A report by MarketsandMarkets indicates that the global MCCB market is projected to reach USD 7.6 billion by 2025, growing at a CAGR of 5.9%. This growth underscores the increasing reliance on advanced circuit protection solutions across industries.

Understanding the basics of electronic MCCBs is crucial for selecting the right device for your application. Unlike traditional thermal-magnetic circuit breakers, electronic MCCBs use sophisticated digital technology to monitor current flow. They can provide precise overcurrent and short circuit protection while accommodating diverse operational conditions. According to a research paper from the IEEE, electronic MCCBs can reduce tripping times by up to 70%, significantly minimizing downtime and improving system reliability. These devices also often incorporate features such as adjustable settings and remote monitoring capabilities, allowing operators to customize performance based on specific requirements.

As energy efficiency becomes a priority in industrial settings, the adoption of electronic MCCBs can lead to substantial savings. The U.S. Department of Energy has highlighted that efficient circuit protection systems can lower electricity consumption and reduce the risk of potential equipment failures, further solidifying the higher value these modern MCCBs bring. In conclusion, investing in the right electronic MCCB not only safeguards circuits but also contributes to a more efficient energy management strategy.

Key Factors to Consider When Selecting an MCCB

When selecting the right electronic Molded Case Circuit Breaker (MCCB) for optimal circuit protection and efficiency, several key factors come into play. Firstly, understanding the application requirements is crucial. The electrical load, operating voltage, and environmental conditions will significantly influence the choice of MCCB. For instance, in environments with high humidity or dust, an MCCB with enhanced ingress protection ratings may be necessary to ensure durability and reliability.

Another critical factor to consider is the MCCB's breaking capacity, which indicates the maximum fault current it can interrupt without being damaged. This is vital to prevent potential hazards in case of electrical faults. Additionally, features such as thermal-magnetic trip settings allow for tailored protection, ensuring that the MCCB responds appropriately to overloads and short circuits. Finally, factors such as size, installation convenience, and compatibility with existing systems should also be assessed to achieve seamless integration and maintain overall efficiency. By paying close attention to these aspects, selecting an MCCB that maximizes protection and operational effectiveness becomes more achievable.

How to Choose the Right Electronic MCCB for Optimal Circuit Protection and Efficiency

| Selection Factor | Description | Impact on Performance |

|---|---|---|

| Voltage Rating | The voltage the MCCB can handle. | Ensures compatibility with the system, preventing over-voltage conditions. |

| Current Rating | The maximum continuous current the MCCB can carry. | Critical for preventing overheating and potential equipment damage. |

| Breaking Capacity | The maximum fault current the MCCB can interrupt. | Determines reliability in fault conditions, prevents circuit damage. |

| Installation Type | How the MCCB is mounted (panel-mounted, wall-mounted, etc.). | Affects space efficiency and ease of access for maintenance. |

| Temperature Rating | Operating temperature range for the MCCB. | Ensures reliable operation under various environmental conditions. |

| Features | Additional features like remote operation, trip delays, etc. | Enhances functionality and customization based on application needs. |

Evaluating Voltage and Current Ratings for Optimal Performance

When selecting an electronic MCCB (Molded Case Circuit Breaker), understanding its voltage and current ratings is crucial for ensuring optimal performance and protection. A well-chosen MCCB not only safeguards the electrical system from overloads and short circuits but also enhances the efficiency of the overall circuit. Current ratings must be evaluated based on the specific application requirements and load conditions. For instance, in renewable energy systems where solar photovoltaics (PVs) are utilized, the PCCBs need to account for the fluctuating nature of power production. Therefore, precise voltage and current ratings, tailored to the anticipated operational scenarios, are essential.

Moreover, advancing technologies such as grid-forming inverters are reshaping energy systems by introducing current-limiting strategies that ensure stability during low voltage ride-through conditions. This is particularly important as the penetration of renewable energy grows, necessitating a careful balance between protection and performance. Understanding the interaction between those inverters and MCCBs can lead to an optimized setup that not only mitigates risks but also promotes higher efficiency in energy distribution. As we integrate more complex systems, the demand for MCCBs that can adapt to variable loads and provide reliable performance becomes paramount.

The Importance of Interrupting Capacity in Circuit Protection

When selecting an electronic Molded Case Circuit Breaker (MCCB), the interrupting capacity is a critical factor that directly influences circuit protection and overall efficiency. Interrupting capacity refers to the maximum fault current that an MCCB can safely interrupt without failure. Choosing an MCCB with an appropriate interrupting capacity ensures that your electrical systems are safeguarded against potential overloads and short circuits. If the interrupting capacity is too low, the breaker may not operate effectively during a fault, leading to failures that could damage equipment or, worse, pose safety risks.

Moreover, understanding the specific requirements of your application is essential. Different environments and load types can influence the maximum fault currents present in a circuit. For example, industrial settings may experience higher fault currents compared to residential applications. Therefore, conducting an accurate analysis of the system's potential fault conditions allows for the selection of an MCCB that not only meets but exceeds the necessary standards for interrupting capacity. This proactive approach fosters a more resilient electrical system, minimizes downtime, and enhances the longevity of the equipment involved.

Tips for Maintaining and Testing Your MCCB for Longevity

When it comes to ensuring the longevity and optimal performance of your Molded Case Circuit Breaker (MCCB), regular maintenance and testing are critical. Start by routinely inspecting the physical condition of the MCCB for signs of wear or damage, such as cracks, discoloration, or signs of overheating. Clean the exterior using a soft, dry cloth to remove dust and debris that may impede its function. Additionally, checking the tightness of connections can prevent failures caused by loose terminals, which is an essential part of prolonging the lifespan of your circuit protection device.

Moreover, implementing a testing schedule can help identify potential issues before they escalate. Conduct routine functional tests to ensure that the MCCB is operating correctly under various load conditions. This includes verifying the trip mechanism and ensuring it reacts as expected during overload scenarios. It's also beneficial to monitor operating temperatures during regular use, as excessive heat can be a precursor to failure. By maintaining a proactive approach to testing and maintenance, you can maximize the efficiency and reliability of your MCCB, safeguarding your electrical circuits for years to come.

How to Choose the Right MCCB for Optimal Circuit Protection and Efficiency

This chart illustrates the importance of selecting the right MCCB based on various factors such as current rating, short-circuit protection, and operating environment to ensure optimal circuit protection and efficiency.

Related Posts

-

10 Amazing Reasons Why Electronic MCCBs Are Essential for Your Business

-

Ultimate Checklist for Choosing the Best Low Voltage Circuit Breaker

-

Ultimate Guide to Selecting the Right Air Circuit Breaker for Your Industrial Needs

-

Unmatched Excellence in Manufacturing by Leading Chinese Factory for Best Electrical MCCB Solutions

-

Understanding Common Issues Faced with Best MCCB Moulded Case Circuit Breakers

-

The Ultimate Guide to Understanding Air Breaker Circuit Breakers: Your Complete Resource

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500