What is an Electric MCCB? Understanding Its Functions, Benefits, and Applications

The evolution of electrical protection devices has led to the increasing adoption of Electric MCCBs (Molded Case Circuit Breakers) in various industrial applications. According to a recent report by Global Market Insights, the Electric MCCB market is anticipated to witness significant growth, with an expected value reaching $2.2 billion by 2027, driven primarily by increasing demand for reliable electric protection and enhanced safety standards in power distribution systems. The ability of Electric MCCBs to provide both overload and short-circuit protection, while safeguarding sensitive electrical circuits, positions them as essential components in modern electrical infrastructures.

Industry expert Dr. Emily Anderson, a well-known authority on electrical safety systems, emphasizes the importance of Electric MCCBs in current electrical applications, stating, "The reliability and efficiency of Electric MCCBs are crucial in minimizing electrical hazards and ensuring the uninterrupted operation of industrial processes." This assertion highlights not only the functional benefits of Electric MCCBs but also their vital role in safeguarding both personnel and equipment against unforeseen electrical faults. As industries continue to expand and modernize, understanding the functions, benefits, and applications of Electric MCCBs becomes increasingly critical for engineers and decision-makers alike.

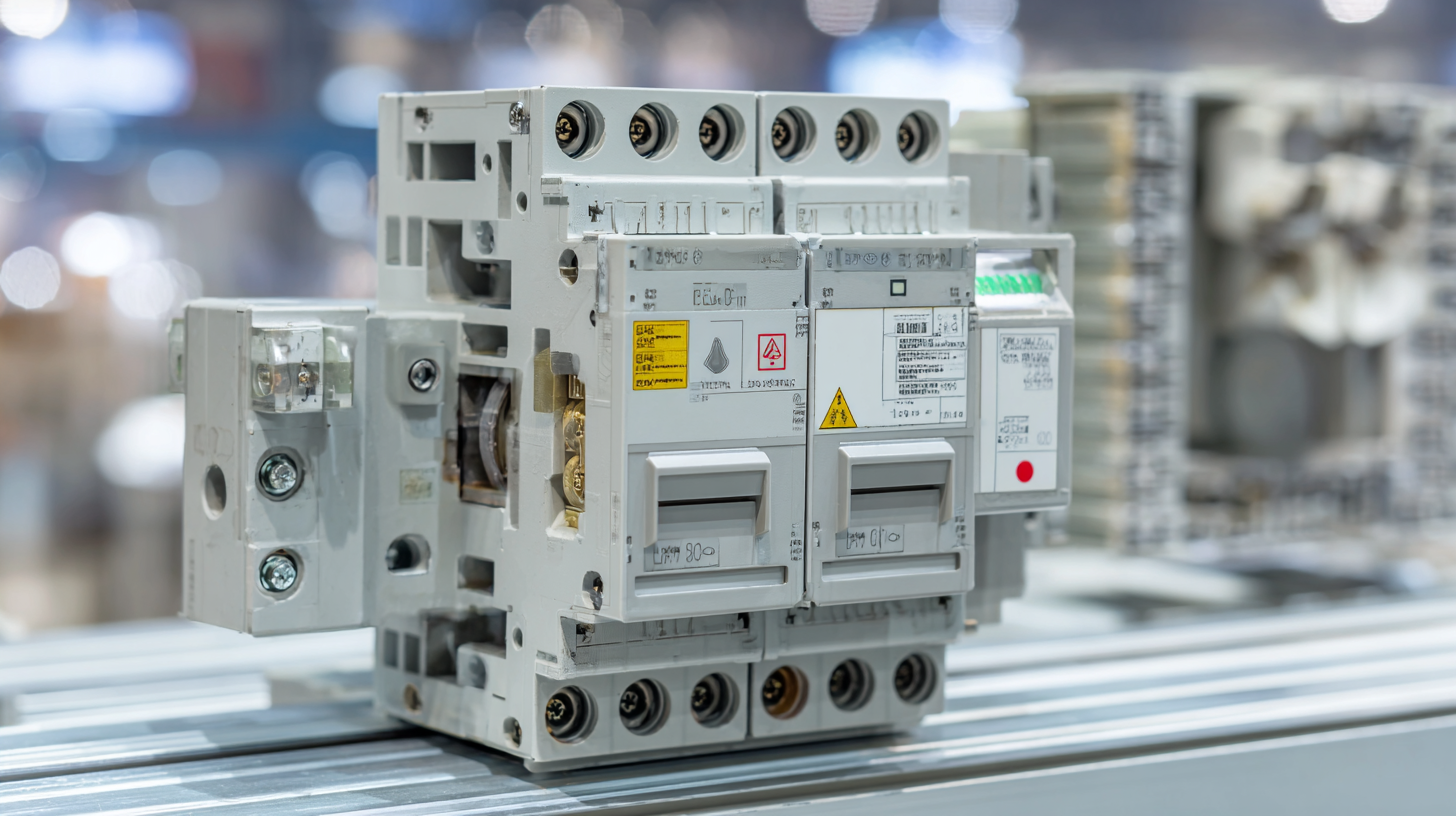

Understanding the Basics of Electric MCCBs: Definition and Key Features

An Electric MCCB, or Molded Case Circuit Breaker, is a critical component in electrical systems designed to provide overcurrent protection and ensure safe operating conditions. At its core, an MCCB functions as a switch that automatically interrupts power to prevent damage caused by overloads or short circuits. This device is specifically engineered to handle a wide range of electrical currents, making it suitable for various applications, from commercial buildings to industrial machinery.

One of the key features of Electric MCCBs is their adjustable trip settings, allowing users to customize the protection level according to their specific requirements. Additionally, MCCBs often come equipped with advanced electronic trip units that provide better accuracy and sensitivity compared to traditional thermal-magnetic breakers. Other notable characteristics include the compact design and reliable performance under heavy-duty conditions, making them an ideal choice for safeguarding electrical installations and ensuring operational efficiency. Their versatility makes MCCBs indispensable in modern electrical systems, contributing to both safety and reliability.

Essential Functions of MCCBs in Electrical Systems: Protection and Control

Electric MCCBs (Molded Case Circuit Breakers) play a crucial role in modern electrical systems, particularly in the context of advanced applications like electric and hybrid propulsion systems. These devices are essential for safeguarding electrical circuits by detecting and interrupting overloads and short circuits, thereby preventing potential damage to equipment and ensuring system reliability. In the rapidly evolving landscape of electric aviation, for instance, MCCBs contribute significantly to enhancing overall performance while simultaneously reducing emissions, addressing crucial demands for efficiency and sustainability.

Beyond protection, MCCBs also facilitate control within electrical systems. They enable seamless integration and operation of sophisticated electrical architectures, such as those found in electric vehicles and innovative industrial solutions. Companies are increasingly recognizing the benefits of incorporating advanced MCCB technology to manage complex electrical environments effectively. This development aligns with the trend toward electrification in various sectors, including transportation and mining, where new electric vehicles are being introduced, filling significant market gaps and fostering industry advancement.

Benefits of Implementing MCCBs: Safety, Reliability, and Cost-Effectiveness

Molded Case Circuit Breakers (MCCBs) play a crucial role in modern electrical systems, providing safety, reliability, and cost-effectiveness. One of the most significant benefits of implementing MCCBs is their ability to offer superior protection against overloads and short circuits. Unlike traditional fuses, MCCBs can be reset after tripping, reducing downtime and maintenance costs. This feature not only enhances the efficiency of electrical operations but also improves the overall safety of electrical installations by preventing potential hazards.

Tips for selecting the right MCCB include evaluating the specific load requirements and understanding the environmental conditions in which the breaker will operate. Consideration of factors such as ambient temperature, moisture, and the presence of corrosive elements can ensure optimal performance and longevity of the circuit breaker.

Additionally, the modular design of MCCBs allows for flexibility in applications, making them suitable for various industries, from manufacturing to commercial buildings. Their comprehensive protection capabilities and ease of integration into existing systems make MCCBs a smart investment for any organization aiming to enhance safety while controlling costs effectively.

Common Applications of Electric MCCBs Across Various Industries

Electric Molded Case Circuit Breakers (MCCBs) are essential components in a variety of industries due to their role in protecting electrical circuits from overloads and short circuits. Common applications of MCCBs span across sectors such as manufacturing, commercial buildings, and energy distribution. In manufacturing, MCCBs regulate and safeguard power supply for machinery, ensuring operational safety and continuity while preventing damage from electrical faults. Their reliability makes them crucial in production environments where uninterrupted power is vital.

In commercial settings, MCCBs are utilized in distribution panels to protect electrical systems, allowing for safe access to power in offices, retail spaces, and data centers. Additionally, their function is pivotal in energy distribution networks, particularly in substations and switching stations, where they help manage loads and protect infrastructure from electrical surges. With this broad applicability, electric MCCBs prove indispensable across various domains, contributing to operational efficiency, safety, and the longevity of electrical systems.

Common Applications of Electric MCCBs Across Various Industries

| Industry | Function | Benefits | Common Applications |

|---|---|---|---|

| Manufacturing | Overcurrent protection, isolation of equipment | Enhances safety, reduces equipment damage | Motor control centers, assembly lines |

| Construction | Protects electrical circuits from overloads | Increases reliability, minimizes downtime | Power supply for heavy machinery |

| Energy Sector | Protects generators and transformers | Ensures system stability, prevents failures | Substations, renewable energy installations |

| Commercial Building | Protection for the electrical distribution system | Improves operational efficiency, enhances safety | Lighting systems, HVAC systems |

| Telecommunications | Protects sensitive electronic equipment | Reduces risk of equipment failure | Data centers, communication networks |

Comparison of MCCBs with Other Circuit Protection Devices: Pros and Cons

Molded case circuit breakers (MCCBs) are essential components in electrical systems, providing automatic switching during overload or short-circuit events. When comparing MCCBs to other circuit protection devices like fuses and miniature circuit breakers (MCBs), several pros and cons arise. According to a report by the International Electrotechnical Commission, MCCBs can handle higher current ratings, typically ranging from 100A to 2500A, making them ideal for industrial applications. They also feature adjustable trip settings, allowing for greater customization based on specific load requirements, which is not a capability offered by traditional fuses.

On the downside, MCCBs can be more expensive and bulkier compared to fuses and MCBs. While a fuse might offer a lower upfront cost and take less space, they lack the reusability and adjustable settings of MCCBs. Furthermore, once a fuse blows, it requires replacement, which can lead to increased downtime. In contrast, MCCBs can simply be reset after a trip, enhancing operational efficiency in environments where electrical reliability is critical. Understanding these distinctions helps engineers and facility managers select the appropriate device for their specific applications.

Comparison of MCCBs with Other Circuit Protection Devices

This chart compares the effectiveness of various circuit protection devices, including MCCBs, Fuses, MCBs, and RCDs on a scale of 1 to 10. MCCBs score the highest due to their advanced features and reliability.

Related Posts

-

5 Essential Tips for Choosing the Right Electronic MCCB for Your Industrial Needs

-

Empowering the World with Chinese Excellence: The Unmatched Best Thermal Magnetic Release MCCB

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

The Future of Innovative Energy Management with Best Air Circuit Breakers

-

12 Reasons Why Best Electronic MCCB Should Be Your Top Choice

-

Understanding Common Issues Faced with Best MCCB Moulded Case Circuit Breakers

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500