5 Essential Tips for Choosing the Best ACB Circuit Breaker for Your Business

In today's competitive business landscape, ensuring the safety and reliability of your electrical systems is paramount, especially while selecting the right protection device for your operations. One critical component that plays a significant role in safeguarding your electrical infrastructure is the ACB circuit breaker. With a variety of options available on the market, including voltage ratings, current capacities, and alternative types, making an informed choice can be daunting. This blog aims to guide you through the essential tips for choosing the best ACB circuit breaker tailored to your business needs. By understanding the functional requirements, testing methods, and variations of ACB circuit breakers, you can make a decision that not only enhances safety but also optimizes performance in your facility. Join us as we delve into the key considerations that will help you navigate the complexities of selecting the ideal ACB circuit breaker for your operations.

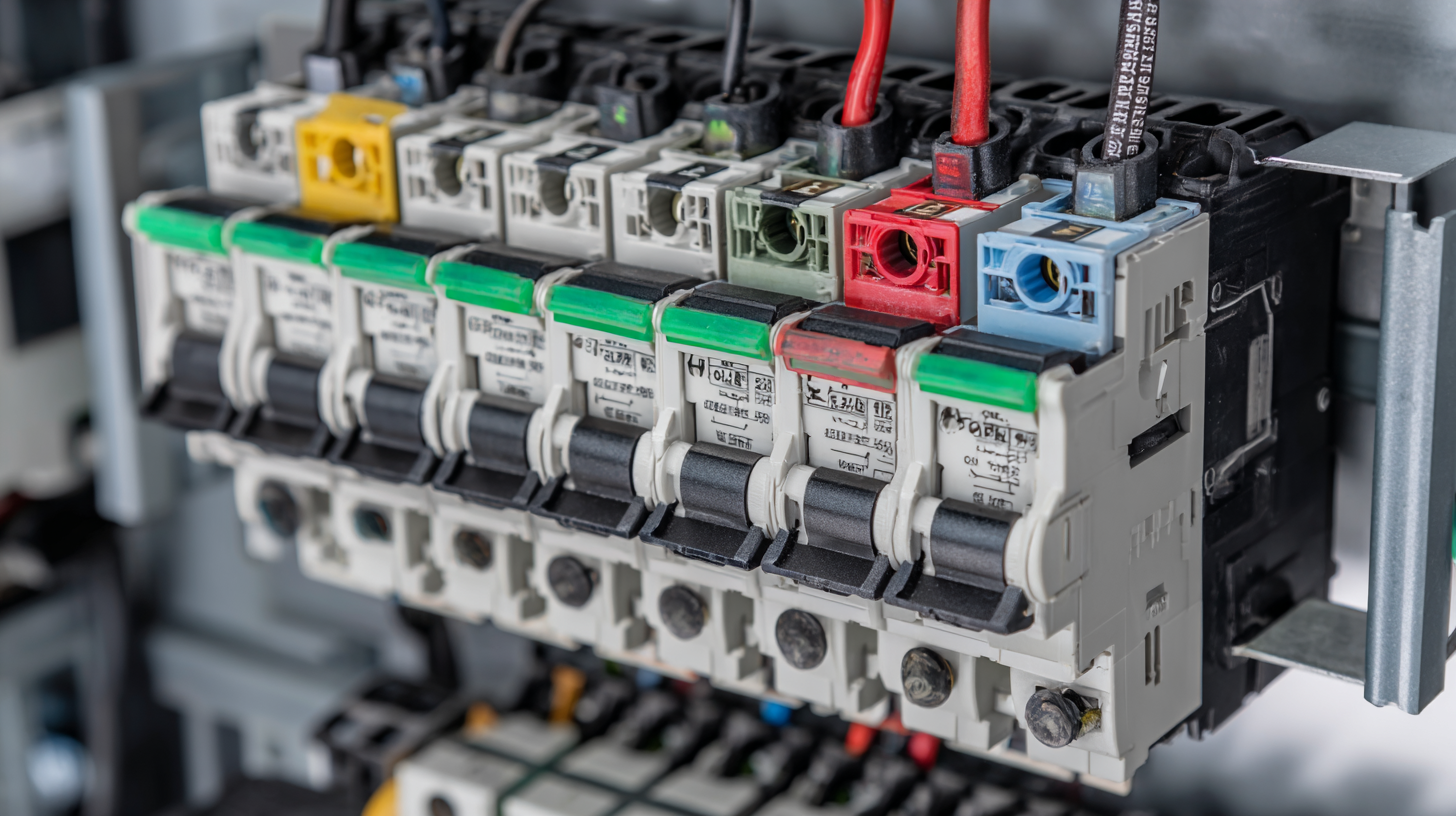

Understanding the Importance of ACB Circuit Breakers in Business Operations

An Air Circuit Breaker (ACB) is a crucial component in ensuring the smooth operation of business facilities, particularly as organizations increasingly rely on stable electrical systems. The demand for ACBs is growing in tandem with the expansion of modern infrastructure; the low voltage DC circuit breaker market, for instance, is projected to reach a staggering $1.55 billion by 2025, eventually escalating to $2.24 billion by 2032. This growth highlights the essential role of circuit breakers in maintaining operational efficiency and safety in various business settings.

Moreover, the European circuit breaker market is witnessing a substantial shift, driven by investments in renewable energy infrastructure and the modernization of aging power grids. By 2024, this market is anticipated to surpass $4.2 billion, indicating a strong emphasis on reliable energy solutions. Such data underscores the importance of selecting the right ACB circuit breaker. Businesses must prioritize factors like durability, response time, and compatibility with existing systems to ensure continuous and safe operation, thereby enhancing overall productivity and minimizing risks associated with electrical failures.

Key Factors to Consider When Selecting ACB Circuit Breakers

When selecting an Air Circuit Breaker (ACB) for your business, several key factors must guide your decision. First and foremost, consider the electrical load requirements of your facility. Understanding the total current demand will help you choose a circuit breaker that can handle the specific load without risk of tripping unnecessarily. Additionally, take into account the short-circuit protection needs; a breaker with adequate interrupting capacity will safeguard your equipment and infrastructure from potential damage due to overloads.

Another crucial aspect is the environment in which the ACB will be installed. Factors such as temperature, humidity, and the presence of corrosive elements can impact the performance and longevity of the circuit breaker. Opting for models that are rated for harsh conditions can enhance operational reliability. Lastly, ensure that the chosen ACB complies with relevant industry standards and regulations. This not only guarantees safety but also provides peace of mind that your business operations align with best practices in electrical management.

Types of ACB Circuit Breakers and Their Applications

When selecting the best Air Circuit Breaker (ACB) for your business, understanding the types and applications of ACBs is crucial. ACBs are classified primarily based on their operating mechanism: magnetic, thermal, and electronic. The thermal ACB operates on the principle of heat generation in conductors, making it suitable for applications where overcurrent protection is necessary, such as in industrial plants.

On the other hand, magnetic ACBs are ideal for applications requiring high-speed tripping for short circuits, which is vital in protecting valuable equipment and ensuring safety in manufacturing environments.

On the other hand, magnetic ACBs are ideal for applications requiring high-speed tripping for short circuits, which is vital in protecting valuable equipment and ensuring safety in manufacturing environments.

In addition to the operating mechanism, ACBs can also be categorized by their voltage ratings. Low-voltage ACBs, typically up to 1,000 volts, are widely used in commercial buildings and light industrial applications, while medium-voltage ACBs (1 kV to 36 kV) are more suited for power distribution centers and heavy industrial applications.

According to a recent report by MarketsandMarkets, the global ACB market is projected to reach $6.5 billion by 2025, reflecting a growing demand for advanced circuit protection solutions across various industries. Understanding these distinctions will enable businesses to make more informed decisions when implementing ACBs in their electrical distribution systems.

Evaluating Power Ratings and Interrupting Capacities for ACBs

When selecting an Air Circuit Breaker (ACB) for your business, evaluating the power ratings and interrupting capacities is crucial for ensuring that your electrical system operates safely and efficiently. Power ratings dictate how much current the ACB can handle without overheating or causing a trip. It’s essential to consider your business's specific power demands, as exceeding the rated capacity can lead to equipment damage and pose safety hazards. Make sure to consult with electrical engineers or use load assessment tools to accurately measure your facility’s needs.

Interrupting capacity, on the other hand, refers to the ACB's ability to safely interrupt fault currents without damaging its internal components. This feature protects your electrical infrastructure from potential overloads and short circuits. When choosing an ACB, look for models with interrupting capacities that exceed the maximum expected fault levels in your system. By carefully evaluating these two metrics, you can ensure that the ACB chosen provides both reliable performance and the necessary safeguards for your business operations.

Power Ratings and Interrupting Capacities of ACBs

This chart displays the power ratings and interrupting capacities of various ACB models, helping businesses assess their options when choosing the best circuit breaker for their electrical needs.

Maintenance and Safety Considerations for ACB Circuit Breakers

When selecting an air circuit breaker (ACB) for your business, maintenance and safety should be at the forefront of your decision-making process. Conducting regular inspections and maintenance routines not only prolongs the life of your ACB but also ensures that it operates efficiently during critical times. With the rise in sophisticated technologies such as artificial intelligence and automation, it is essential to incorporate real-time monitoring features that can alert you to potential issues. This capability not only enhances operational reliability but also addresses growing concerns about energy consumption and grid stability.

Furthermore, understanding the safety standards and regulations governing electrical equipment is crucial. A well-maintained ACB can prevent hazardous situations, helping to safeguard both personnel and property. Industries are increasingly prioritizing safety measures, which include selecting breakers with advanced safety features that can withstand varied demands. The move toward more sustainable and circular-ready products highlights the importance of choosing ACBs designed to handle rigorous conditions while contributing to overall energy efficiency. Prioritizing these maintenance and safety considerations will ensure your electrical infrastructure supports the reliable operation of your business.

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500