7 Essential Tips for Choosing the Best Acb Circuit Breaker for Your Industrial Needs

When it comes to ensuring the safety and efficiency of your industrial operations, selecting the right ACB Circuit Breaker is paramount. These devices serve as critical protective components, safeguarding electrical circuits from overload and short circuits, thereby preventing potential damage to machinery and facilities. With the diverse array of ACB Circuit Breakers available in the market, making an informed decision can be overwhelming. This blog aims to provide seven essential tips to guide you through the selection process, focusing on key technical specifications and practical considerations. By understanding the functionality, ratings, and features of different ACB Circuit Breakers, you will be better equipped to make a choice that aligns with your specific industrial needs, ultimately enhancing the reliability and safety of your electrical systems.

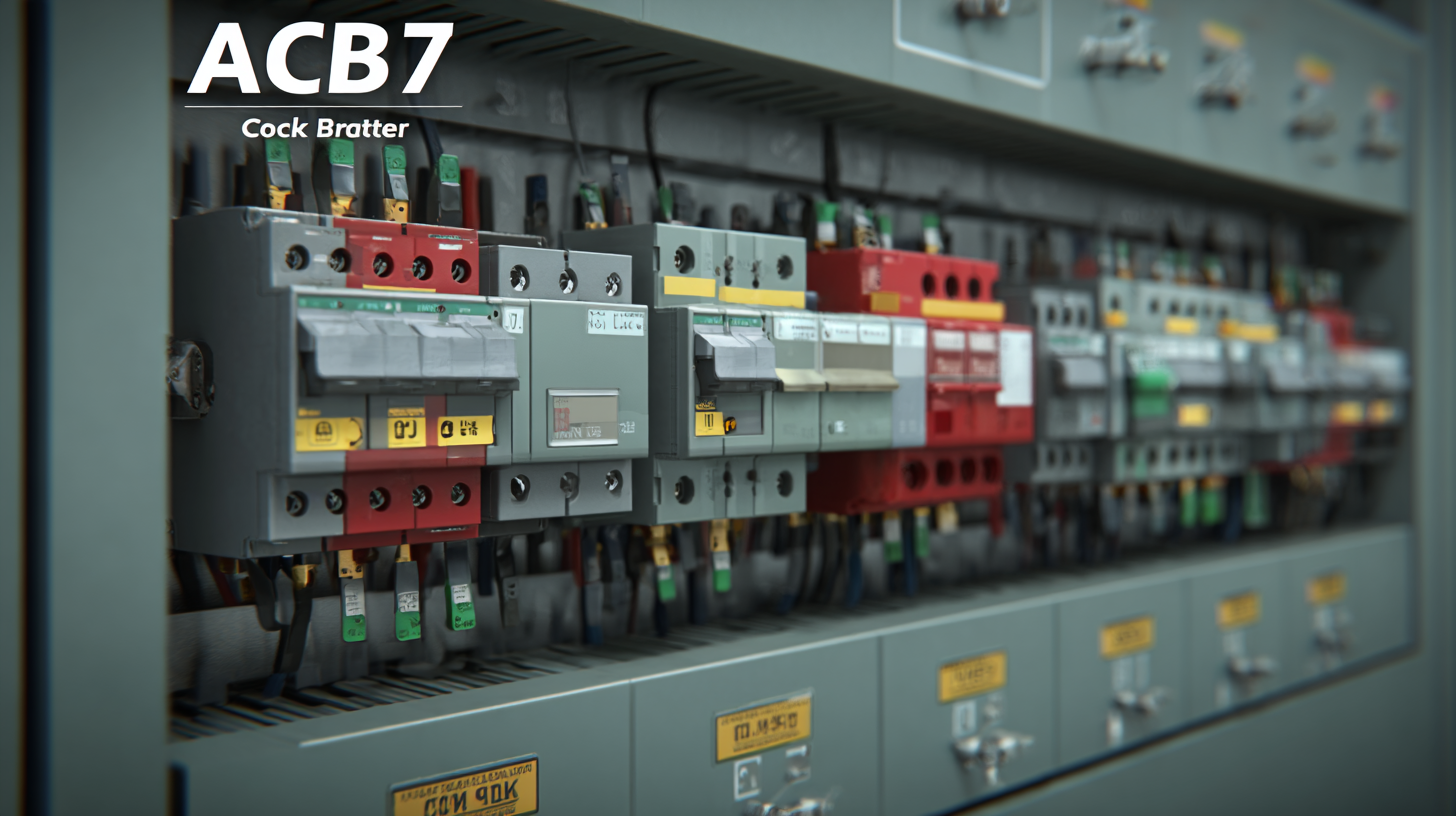

Understanding Different Types of ACB Circuit Breakers: Key Features and Applications

When selecting an Air Circuit Breaker (ACB) for industrial applications, understanding the different types and their key features is crucial. ACBs are primarily categorized based on their operating mechanisms—electromechanical or electronic. Electromechanical ACBs are often favored for their simplicity and reliability, while electronic ACBs offer advanced functionalities such as precise fault detection and monitoring capabilities. Identifying the right type based on your specific industry requirements will enhance operational efficiency and safety.

One essential tip is to consider the voltage and current ratings of the ACB. Ensure that the selected breaker can handle the maximum load of your electrical system to prevent potential overloads. Additionally, assess the environmental conditions where the ACB will be installed. Features such as dust and moisture resistance can significantly impact the longevity and performance of the circuit breaker.

Another crucial consideration is the ACB's protection features. Look for models equipped with adjustable settings for the trip curves and overcurrent protection. This flexibility allows for customization to specific applications, contributing to the protection of your equipment against faults. Emphasizing these key features will help in making an informed choice tailored to your industrial needs.

Evaluating Rated Current and the Importance of Load Calculation in ACB Selection

When selecting an Air Circuit Breaker (ACB) for industrial applications, understanding the rated current and executing a thorough load calculation are paramount. The rated current indicates the maximum load the circuit breaker can handle without tripping. It’s essential to match this rating with the expected current in your specific application to ensure safety and reliability. A lower rated current may cause frequent tripping, while a higher rating can lead to inadequate protection against overloads.

Furthermore, load calculation plays a crucial role in this selection process. An accurate load calculation involves assessing the total current demand of all connected devices and considering factors such as starting currents, peak loads, and continuous operating conditions. This evaluation helps in determining an appropriate ACB size that not only meets current operational needs but also accommodates future expansions or increases in demand. By prioritizing these elements, industries can enhance their electrical safety measures and optimize performance efficiency in their operations.

Exploring Tripping Characteristics: Thermal vs. Magnetic Protection in ACBs

When selecting an Air Circuit Breaker (ACB) for industrial applications, understanding the tripping characteristics is crucial. Two primary protection mechanisms are thermal and magnetic tripping, each serving distinct functions. Thermal protection is essential for long-term overload situations; it operates based on heat generation caused by excessive current flowing through the circuit. This mechanism can prevent damage to equipment by allowing the ACB to trip slowly under moderate overloads, providing valuable time for processes to adjust or operators to react.

On the other hand, magnetic protection offers instantaneous response to short circuits or severe overloads. This mechanism uses electromagnetic forces to activate the tripping mechanism immediately, minimizing the potential for damage to machinery and preventing fire hazards. Choosing between thermal and magnetic protection hinges on the specific industrial requirements: processes that frequently experience overloads may benefit more from thermal protection’s gradual response, while those that demand quick action in emergencies should lean towards magnetic protection for its rapid response capabilities. Understanding these dynamics will help ensure the selected ACB can effectively safeguard your operational integrity.

7 Essential Tips for Choosing the Best ACB Circuit Breaker for Your Industrial Needs

| Tip | Description | Tripping Characteristics | Protection Type |

|---|---|---|---|

| 1. Understand Load Requirements | Assess the electrical load and operational requirements. | Consider both inrush and steady-state current. | Both Thermal and Magnetic |

| 2. Select the Right Frame Size | Choose based on the maximum circuit current. | Thermal protections are often size-dependent. | Thermal |

| 3. Evaluate Short-Circuit Protection | Consider the maximum fault level of your installation. | Magnetic protection is crucial here. | Magnetic |

| 4. Assess Reset Mechanisms | Look for automatic or manual reset features. | Impact operational downtime. | Both |

| 5. Investigate Environmental Conditions | Determine if ACB will be used in harsh conditions. | Thermal protections may derate. | Thermal |

| 6. Review Coordination Requirements | Ensure proper fault current distribution. | Synchronization of tripping characteristics. | Both |

| 7. Consider Maintenance and Inspection | Plan for regular checks and maintenance schedules. | Prolongs lifespan of protections. | Both |

Assessing Environmental Conditions: Choosing ACBs for Harsh Industrial Settings

When selecting air circuit breakers (ACBs) for harsh industrial environments, it's crucial to evaluate the environmental conditions they will face. ACBs must be able to withstand extreme temperatures, humidity, and potential exposure to pollutants. According to recent industry reports, approximately 30% of equipment failures in manufacturing settings are attributed to inadequate protection against harsh environmental conditions. This highlights the importance of choosing ACBs that are designed with enhanced insulation and protection features.

Additionally, manufacturers are increasingly focused on delivering solutions that ensure secure power connections even in difficult circumstances. Research indicates that specialized ACBs can reduce downtime by up to 40% when deployed in challenging environments. Selecting ACBs that meet specific environmental ratings—such as IP ratings for dust and moisture resistance—can significantly increase reliability and operational efficiency. Industries that experience fluctuations in temperature and humidity must prioritize their choice of circuit breakers to prevent costly interruptions and ensure safety in their operations.

Compliance and Standards: Ensuring ACBs Meet Industry Regulations and Safety Protocols

When selecting an Air Circuit Breaker (ACB) for industrial applications, compliance with industry regulations and safety protocols is paramount. ACBs must not only protect your equipment but also align with the relevant standards set forth by regulatory bodies. Understanding these requirements ensures that your ACBs will operate safely and efficiently, reducing the risks of equipment failure and workplace accidents. Familiarizing yourself with the specific compliance standards applicable in your region, such as IEC standards or national electrical codes, will provide a solid foundation for your decision-making process.

In addition to adhering to compliance standards, it is essential to evaluate the safety features integrated into the ACB design. Look for breakers that offer advanced protection mechanisms, like overcurrent and earth fault protection, to safeguard against potential hazards. Furthermore, ensure the ACB's installation and operational guidelines are easy to follow, as adherence to these instructions is crucial for maintaining compliance. By placing a strong emphasis on industry regulations and safety protocols, you will be better equipped to choose an ACB that not only meets your operational needs but also prioritizes the safety of your facility and workforce.

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500