5 Essential Tips for Choosing the Right Electronic MCCB for Your Industrial Needs

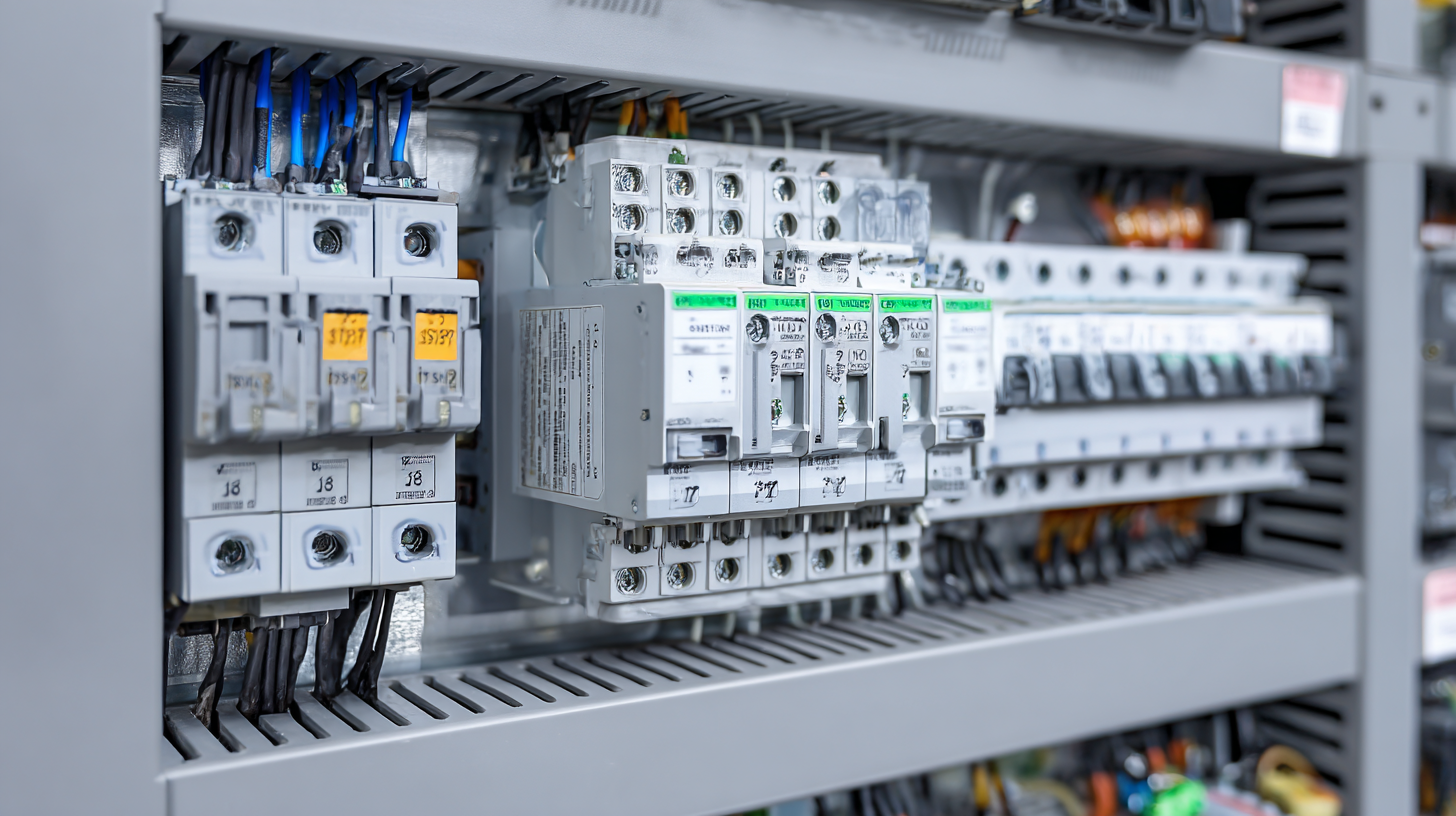

When it comes to ensuring reliable and efficient power distribution in industrial settings, choosing the right Electronic MCCB (Molded Case Circuit Breaker) is crucial. With an array of options available on the market, understanding the key features and specifications of these devices can significantly impact both safety and operational performance. This guide serves to provide essential tips for selecting the most suitable Electronic MCCB to meet your specific industrial needs.

By exploring aspects such as current ratings, breaking capacity, and additional functionalities, you can make an informed decision that enhances system reliability while minimizing downtime. As the demands of modern industries evolve, the importance of selecting the appropriate Electronic MCCB cannot be overstated, making this guide a valuable resource for professionals looking to optimize their electrical systems.

By exploring aspects such as current ratings, breaking capacity, and additional functionalities, you can make an informed decision that enhances system reliability while minimizing downtime. As the demands of modern industries evolve, the importance of selecting the appropriate Electronic MCCB cannot be overstated, making this guide a valuable resource for professionals looking to optimize their electrical systems.

Understanding the Basics of Electronic MCCBs: Key Features and Functions

Understanding the basics of Electronic Molded Case Circuit Breakers (MCCBs) is crucial for industrial applications. Electronic MCCBs are sophisticated devices that provide a range of features superior to traditional thermal-magnetic breakers. They are designed to ensure reliable circuit protection while enhancing operational efficiency. Key features of these breakers include adjustable trip settings, which allow users to tailor the protection for specific load requirements, and integrated communication capabilities that facilitate monitoring and analysis of electrical parameters in real-time.

In addition to these features, electronic MCCBs come equipped with innovative functions such as ground fault detection and phase imbalance protection. These capabilities provide an added layer of safety by quickly identifying and isolating fault conditions, which helps to reduce equipment damage and downtime. Furthermore, the digital display on many electronic MCCBs enables easy access to operational data and diagnostics, aiding in proactive maintenance planning. Understanding these key aspects is essential for making informed decisions and optimizing your industrial electrical system’s performance.

Evaluating Current Ratings: Aligning MCCB Capacity with Industrial Power Needs

When selecting the right electronic Molded Case Circuit Breaker (MCCB) for industrial applications, evaluating current ratings is crucial to ensure optimal performance and safety. According to industry reports, such as those from the International Electrotechnical Commission (IEC), properly sizing MCCBs based on the specific load requirements is essential to prevent both nuisance tripping and equipment damage. An MCCB's current rating should not only match the standard operational current of your machinery but also accommodate potential overloads and short-circuit conditions.

For instance, if your facility's machinery operates primarily at an average load of 70% of the maximum capacity, selecting an MCCB with a rating that reflects this is vital. Industry standards recommend a minimum safety margin—typically around 125-150% of the average load—to ensure reliable performance under unexpected surges. This approach helps in mitigating risks outlined in various IEEE reports, which indicate that improper current ratings can lead to severe operational issues, including shutdowns and increased maintenance costs. By aligning MCCB capacity with industrial power needs, facilities can enhance their operational efficiency while safeguarding critical infrastructure from electrical faults.

5 Essential Tips for Choosing the Right Electronic MCCB for Your Industrial Needs

| Tip Number | Tip Description | Current Rating (A) | Application Suitability |

|---|---|---|---|

| 1 | Identify your industrial power needs | 100 | Light Industrial Use |

| 2 | Consider future load requirements | 200 | General Manufacturing |

| 3 | Assess short-circuit protection requirements | 300 | Heavy Machinery |

| 4 | Evaluate operational environment | 400 | Outdoor Applications |

| 5 | Check for compliance with standards | 500 | High Voltage Environments |

Assessing Protection Categories: Choosing Between Standard and Advanced Options

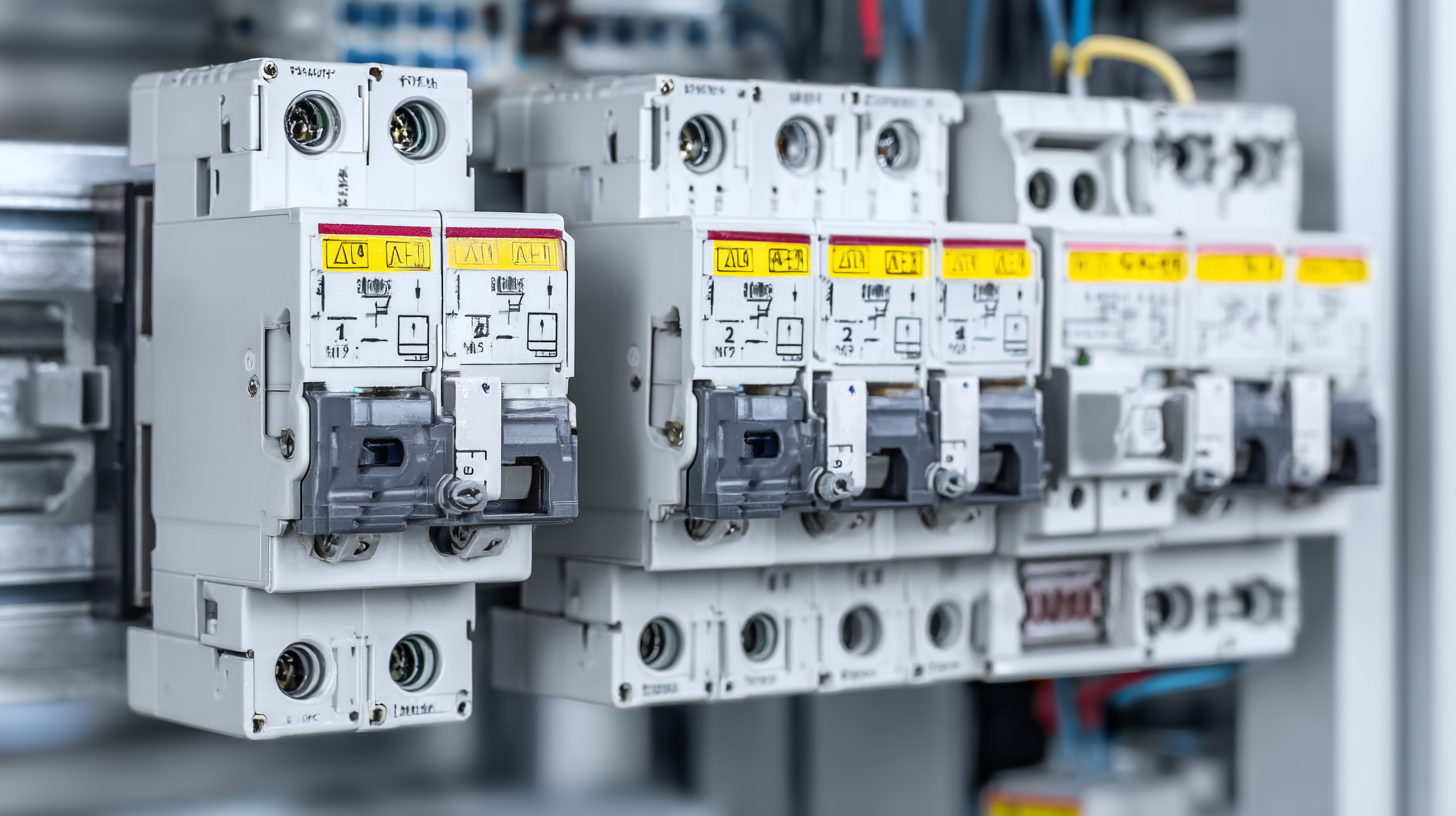

When selecting an electronic Molded Case Circuit Breaker (MCCB) for industrial applications, assessing protection categories is crucial. The choice between standard and advanced options can significantly impact system reliability and safety. Standard MCCBs typically provide basic protection against overloads and short circuits, making them suitable for general industrial uses. However, they may lack the sophisticated features required for more demanding environments.

On the other hand, advanced MCCBs offer enhanced functionalities such as adjustable trip settings, environmental resilience, and integrated communication capabilities. These features allow for tailored protection based on specific operational parameters and conditions. Industries with critical processes or sensitive equipment should prioritize advanced options to mitigate risks and ensure compliance with stringent safety regulations. By carefully evaluating the protection categories and aligning them with industrial requirements, organizations can enhance operational efficiency and reduce downtime effectively.

Exploring Additional Features: Remote Monitoring and Smart Technologies in MCCBs

When selecting an electronic Molded Case Circuit Breaker (MCCB) for industrial applications, additional features such as remote monitoring and smart technologies can significantly enhance operational efficiency and safety. Remote monitoring capabilities allow for real-time tracking of electrical parameters, enabling operators to identify potential issues before they escalate into serious problems. This proactive approach not only helps in maintaining equipment longevity but also minimizes downtime, ensuring that production processes remain uninterrupted.

Furthermore, the integration of smart technologies in MCCBs offers advanced functionalities like predictive maintenance and automated fault detection. These features leverage data analytics to predict equipment failures, allowing businesses to schedule maintenance only when necessary, thus optimizing resource allocation. Additionally, smart MCCBs can be integrated into broader building management systems, providing a cohesive platform for energy management and overall operational oversight. Embracing these advanced features in MCCBs can lead to significant improvements in both productivity and safety in industrial environments.

Considering Installation Compatibility: Ensuring Seamless Integration with Existing Systems

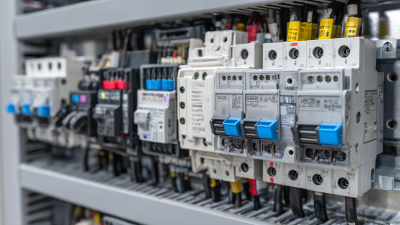

When selecting an electronic Molded Case Circuit Breaker (MCCB) for industrial applications, installation compatibility plays a critical role in ensuring seamless integration with existing systems. Before making a decision, it's essential to assess the current electrical infrastructure, including panel size, busbar configuration, and the specifications of existing circuit protection devices. This evaluation helps in identifying an MCCB that not only fits physically but also operates harmoniously with other components in the electrical system.

Moreover, ensure that the chosen MCCB is compatible with the overall electrical load and system requirements. Considering factors such as rated current, trip settings, and operational environment will help in maintaining the reliability and safety of the installation. Engaging with a qualified engineer can provide valuable insights into selecting a breaker that supports communication protocols and meets regulatory standards, thereby enhancing the efficiency and safety of the industrial operations. Investing time in these considerations upfront can prevent costly modifications and downtime in the future.

Related Posts

-

Empowering the World with Chinese Excellence: The Unmatched Best Thermal Magnetic Release MCCB

-

12 Reasons Why Best Electronic MCCB Should Be Your Top Choice

-

The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500