10 Essential Tips for Understanding Electronic Circuit Breakers

In the realm of electrical safety, understanding the nuances of the Electronic Circuit Breaker is paramount. Experts in the industry, such as Dr. Alice Thompson, a leading electrical engineer, emphasize the importance of this device in preventing electrical faults. Dr. Thompson once stated, "An Electronic Circuit Breaker is not just a safety device; it’s an essential component of modern electrical systems that ensures both efficiency and protection."

The transition from traditional fuses to electronic circuit breakers has revolutionized how we approach electrical safety. Unlike conventional fuses that blow out, electronic circuit breakers can reset, allowing for a more resilient and customizable electrical system. This adaptability makes them an integral part of any sophisticated electrical setup, whether in residential, commercial, or industrial applications. Understanding their functionality and the critical role they play can empower users to make informed decisions about their electrical infrastructure.

In this guide, we will explore ten essential tips that will enhance your understanding of Electronic Circuit Breakers. From basic principles to advanced features, this comprehensive insight will help you appreciate their pivotal role in safeguarding our electrical systems against hazards and improving overall performance.

Understanding the Basics of Electronic Circuit Breakers

Understanding electronic circuit breakers is crucial for anyone working with electrical systems. Unlike traditional fuses, electronic circuit breakers offer advanced protection through modern technology, allowing them to reset automatically after a fault is cleared. This means that users can maintain their equipment with minimal downtime and better manage energy consumption.

One essential tip for understanding electronic circuit breakers is to become familiar with their operating principles. These devices measure current flow and can detect irregularities, such as overloads or short circuits. When a fault is detected, the electronic circuit breaker swiftly interrupts the current, preventing damage to the electrical system. Additionally, many electronic circuit breakers come equipped with features such as surge protection, which can further shield connected devices from voltage spikes.

Another important aspect to consider is the sensitivity settings of these breakers. Different applications may require different sensitivity levels; for instance, a sensitive setting might be necessary in a residential environment to protect against small faults, while a more robust setting could be suitable for industrial applications. Always ensure that your electronic circuit breaker is properly calibrated to suit your specific needs, maximizing efficiency and safety.

Types of Electronic Circuit Breakers and Their Applications

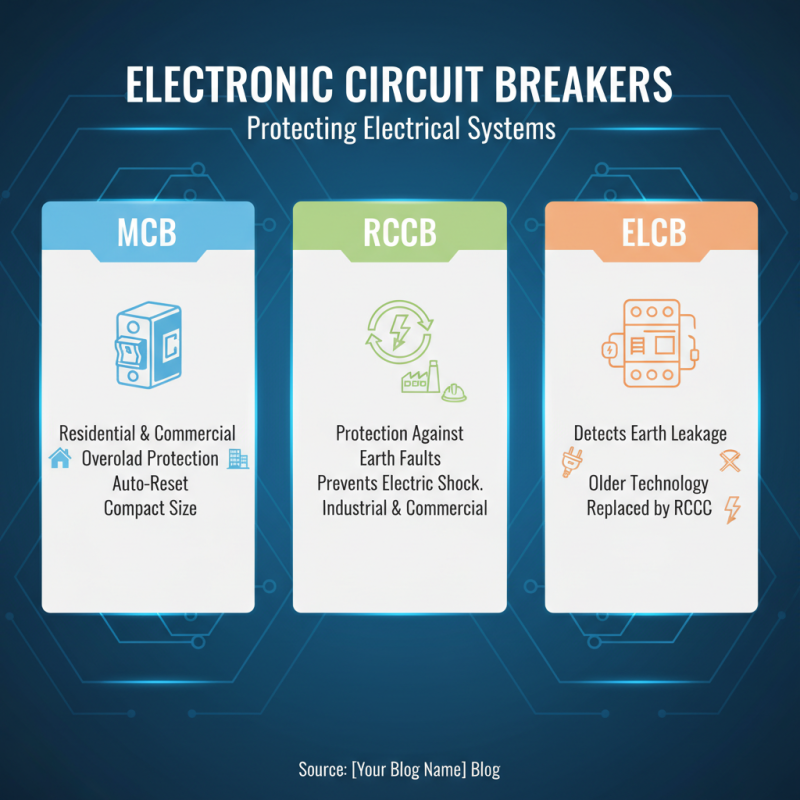

Electronic circuit breakers play a crucial role in protecting electrical systems from overloads and short circuits. There are several types of electronic circuit breakers, each designed to suit specific applications. The most common categories include miniature circuit breakers (MCBs), residual current circuit breakers (RCCBs), and earth leakage circuit breakers (ELCBs). MCBs are ideal for residential and commercial buildings, as they offer protection against overloads and can automatically reset once the fault is cleared. Their compact size makes them suitable for installation in tight spaces, contributing to their widespread use in household electrical distribution.

RCCBs, on the other hand, are vital for preventing electric shocks, as they detect imbalances between outgoing and incoming currents. These devices are essential in wet or high-risk environments, such as bathrooms or outdoors, where the chances of electrocution are heightened. Similarly, ELCBs are designed to protect against ground faults by disconnecting the circuit when leakage is detected. Understanding these distinctions and applications enables users to select the appropriate type of electronic circuit breaker for their specific needs, ensuring safety and reliability in the electrical infrastructure.

Key Components and Functions of Electronic Circuit Breakers

Electronic circuit breakers are sophisticated devices designed to provide protection against overloads and short circuits in electrical systems. Understanding their key components and functions is crucial for effective usage. At the heart of these devices is the sensing mechanism, which monitors the current flowing through the circuit. If the current exceeds a predetermined threshold, the breaker trips, cutting off power to prevent damage to the circuit or connected equipment.

In addition to the sensing mechanism, electronic circuit breakers often include a control circuit, which processes the data from the sensors and initiates the tripping action. This control circuit can also include features such as time-delay options, allowing for temporary surges that do not necessarily indicate a fault condition. Furthermore, the reset mechanism is integral to electronic circuit breakers, providing a straightforward means to restore functionality after addressing the underlying issue. Together, these components work seamlessly to ensure electrical safety and reliability in a wide range of applications.

How to Install and Maintain Electronic Circuit Breakers

When it comes to installing electronic circuit breakers, the first step is to ensure that you have a thorough understanding of the electrical system in your home or workplace. It's essential to assess the existing wiring and determine the appropriate specifications for the circuit breaker you'll be installing. Start by turning off the main power supply to avoid any electrical hazards during installation. Carefully follow the manufacturer’s instructions regarding the correct placement and connection of the circuit breaker. This step typically involves securing the breaker in the panel and making sure the wires are properly aligned and tightened.

Maintenance of electronic circuit breakers is equally crucial for their longevity and effectiveness. Regular inspection should be conducted to check for any signs of wear, corrosion, or damage. It's advisable to periodically test the breaker by turning it off and then back on to ensure it's functioning correctly. Dust accumulation can affect performance; hence, keeping the circuit breaker clean is important. Additionally, if you notice any unusual behavior such as frequent tripping, it may indicate a larger issue in the circuit, necessitating a professional evaluation. Maintaining awareness of the operational parameters and promptly addressing any concerns can significantly enhance safety and reliability in your electrical systems.

Common Issues and Troubleshooting Tips for Circuit Breakers

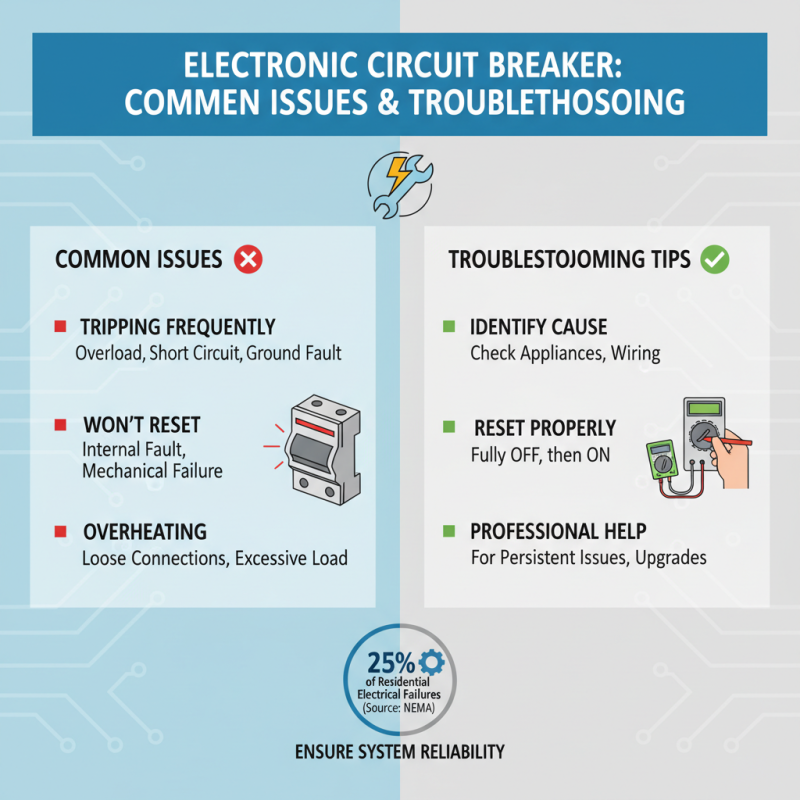

When dealing with electronic circuit breakers, understanding common issues and their troubleshooting techniques is crucial for ensuring the longevity and reliability of your system. Circuit breakers are vital components in protecting electrical circuits from overload and short circuits. According to the National Electrical Manufacturers Association (NEMA), circuit breakers account for approximately 25% of electrical failures in residential settings, underscoring the necessity for proactive maintenance and effective troubleshooting.

One common issue is the tripping of circuit breakers, which can arise from overloaded circuits, faulty wiring, or defective breakers themselves. The U.S. Department of Energy notes that an estimated 50% of circuit breaker trips can be attributed to overload conditions, prompting users to distribute their electrical load evenly across circuits. Troubleshooting often involves resetting the breaker, inspecting for overloaded circuits, and examining connections for signs of wear or damage. If a breaker continues to trip frequently after these checks, replacement may be necessary, as persistent tripping can indicate an underlying fault that could compromise overall safety.

Another frequent problem is the failure of breakers to reset after being tripped. This can stem from internal mechanical failures or electrical faults within the circuit. Research from the International Electrotechnical Commission (IEC) suggests that regular inspection, including visual checks for burns, melts, or unusual noises, can help identify potential issues before they escalate. Implementing routine maintenance practices, such as checking connections and cleaning terminals, can enhance performance and reduce the incidence of circuit breaker malfunctions, ensuring safer electrical system operations.

Related Posts

-

Understanding the Advantages of Using Electronic Circuit Breakers in Modern Electrical Systems

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

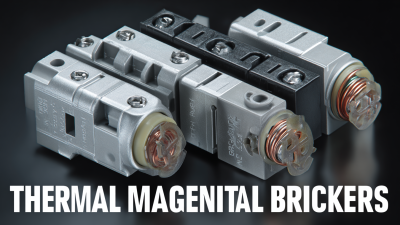

Exploring the Unique Features and Applications of Best Thermal Magnetic Circuit Breakers with Practical Usage Tips

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

Ultimate Guide to Understanding Molded Case Circuit Breakers for Global Procurement

-

2025's Top 10 MCCB Circuit Breakers: Best Choices for Reliable Protection

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500