Unmatched Excellence in Manufacturing Best China Molded Case Circuit Breakers for Global Standards

In the rapidly evolving landscape of electrical distribution management, the demand for high-quality protective devices is more critical than ever. The China Molded Case Circuit Breaker (MCCB) market is experiencing substantial growth, driven by increasing construction activities and rising awareness of safety standards across various industries. According to a recent market research report, the global MCCB market is projected to reach USD 10.3 billion by 2026, with a significant contribution from the Asia-Pacific region, particularly China. As global standards for electrical safety and efficiency become more stringent, manufacturers in China are stepping up to the plate, showcasing unmatched excellence in their production processes and innovation. This blog will explore the exceptional quality and technological advancements in China Molded Case Circuit Breakers, emphasizing their vital role in meeting international safety standards and industry requirements.

Unveiling the Advantages of Molded Case Circuit Breakers in Modern Manufacturing

In modern manufacturing, Molded Case Circuit Breakers (MCCBs) have emerged as a vital component for ensuring electrical safety and efficiency. These devices not only protect against overloads and short circuits but also help maintain system stability in high-demand environments. According to a recent industry report by MarketsandMarkets, the global MCCB market is projected to reach $7.28 billion by 2025, driven by increasing industrial automation and stringent safety regulations. The compact design of MCCBs allows for easier integration into machinery and panel boards, making them a preferred choice for various manufacturing applications.

**Tips:** When selecting MCCBs for your operations, consider the specific voltage ratings and interrupting capacities needed for your systems. Utilizing programmable MCCBs can also enhance flexibility by allowing for custom settings to cater to varying load conditions.

The advantages of MCCBs extend beyond simply safeguarding equipment. They are designed for quick diagnostics, often including features such as thermomagnetic protection and electronic trip units that provide real-time data about electrical consumption. According to Schneider Electric, utilizing MCCBs can improve the responsiveness of a manufacturing facility, leading to optimized operational efficiency and potential energy savings of up to 20%.

**Tips:** Regular maintenance and testing of MCCBs are essential to ensure their longevity and effectiveness. Implementing a monitoring system can help predict failures and reduce unexpected downtimes, enhancing overall productivity in your manufacturing processes.

Unmatched Excellence in Manufacturing Best China Molded Case Circuit Breakers for Global Standards

| Feature | Description | Benefits | Application Areas |

|---|---|---|---|

| Overload Protection | Prevents circuit damage from overload conditions. | Enhanced safety and longevity of electrical systems. | Industrial machinery, HVAC systems. |

| Short Circuit Protection | Protects against sudden surges in electrical current. | Prevents equipment failure and fire hazards. | Commercial buildings, data centers. |

| Adjustable Settings | Allows users to modify the settings based on their needs. | Customized protection levels for different applications. | Manufacturing plants, automation systems. |

| High Breaking Capacity | Designed to handle high fault currents safely. | Improved reliability in high-demand environments. | Power generation sites, heavy industrial applications. |

| Compact Design | Space-saving design simplifies installation. | Saves valuable space in control panels. | Commercial installations, residential buildings. |

Understanding the Global Standards for Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) are essential components in electrical systems, serving as crucial protective devices. Understanding the global standards for these breakers is vital for manufacturers and users alike. According to a recent report by MarketsandMarkets, the global circuit breaker market is projected to reach USD 13.2 billion by 2025, driven by the increasing demand for reliable electrical infrastructure. Compliance with international standards such as IEC 60947-2 ensures that MCCBs maintain operational efficiency and safety in diverse applications.

Molded Case Circuit Breakers (MCCBs) are essential components in electrical systems, serving as crucial protective devices. Understanding the global standards for these breakers is vital for manufacturers and users alike. According to a recent report by MarketsandMarkets, the global circuit breaker market is projected to reach USD 13.2 billion by 2025, driven by the increasing demand for reliable electrical infrastructure. Compliance with international standards such as IEC 60947-2 ensures that MCCBs maintain operational efficiency and safety in diverse applications.

Tips for manufacturers include regularly auditing production processes to ensure compliance with these global standards. Implementing a robust quality management system can significantly reduce non-conformance with regulations, thereby enhancing product reliability. Additionally, manufacturers should invest in training for their workforce about the latest advancements in MCCB technology and standards.

Another crucial aspect to consider is the environmental impact. As sustainability becomes a focal point in design and production, adhering to standards such as RoHS and REACH becomes increasingly essential. Not only does this ensure compliance with regulations, but it also aligns with the growing consumer preference for eco-friendly products. Engaging with these standards can place manufacturers at a competitive advantage in the global market.

Key Benefits of High-Quality Molded Case Circuit Breakers in Industrial Applications

In the fast-paced world of industrial applications, the significance of high-quality molded case circuit breakers (MCCBs) cannot be overstated. These devices serve as pivotal components in electrical systems, providing critical protection against overloads and short circuits. One of the key benefits of employing top-tier MCCBs is their reliability. Constructed with advanced materials and technology, they ensure consistent performance under various operational conditions, ultimately safeguarding sensitive equipment and improving system longevity.

Moreover, high-quality molded case circuit breakers are designed with efficiency in mind. They feature precise trip settings that can be calibrated to suit specific industrial requirements, allowing for tailored protection that reduces downtime due to false tripping. This adaptability not only enhances operational efficiency but also contributes to cost savings by minimizing maintenance and replacement needs. When industries adopt MCCBs that meet global standards, they invest in safety and reliability, which are paramount for sustaining productivity in competitive markets.

Integrating Advanced Technology in Molded Case Circuit Breakers: Enhancing Safety and Efficiency

In the competitive landscape of electrical components, molded case circuit breakers (MCCBs) play a crucial role in ensuring safety and efficiency in various applications. The integration of advanced technology in MCCBs not only enhances their performance but also aligns them with global safety standards. According to a report by MarketsandMarkets, the global MCCB market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is largely driven by increasing demand for energy-efficient solutions and the implementation of strict safety regulations across diverse sectors.

The advancement in MCCB technology includes features such as digital trip units and remote monitoring capabilities. These innovations allow for real-time data tracking and predictive maintenance, thus reducing system downtime and improving overall operational efficiency. A study from the International Journal of Electrical Power & Energy Systems highlights that implementing smart MCCBs can lead to a 20% reduction in energy consumption, making them not just a safety measure but also a strategic investment for businesses looking to optimize their energy management practices. As manufacturers continue to push the envelope in technology integration, the benefits of enhanced safety and efficiency are becoming increasingly evident, setting new benchmarks in the industry.

Performance Overview of Molded Case Circuit Breakers

This chart presents the performance metrics of molded case circuit breakers (MCCBs) based on safety and efficiency standards. The data highlights the efficiency percentage, safety ratings, and market share across different models available globally.

Market Trends: The Growing Demand for High-Performance Molded Case Circuit Breakers in Asia Pacific

The Asia Pacific region is witnessing a significant surge in the demand for high-performance molded case circuit breakers (MCCBs), driven by rapid industrialization and infrastructural development. According to a recent industry report by Markets and Markets, the global molded case circuit breaker market is projected to grow from USD 3.4 billion in 2020 to USD 5.1 billion by 2025, with the Asia Pacific region expected to account for a substantial market share during this period. This growth is largely attributed to the increasing adoption of advanced electrical systems in various sectors, including manufacturing, renewable energy, and residential applications.

In particular, countries like China and India are investing heavily in their electrical infrastructure, responding to the rising demand for reliable power distribution. The International Energy Agency (IEA) notes that Asia Pacific's urban population is expected to grow by over 1 billion by 2040, leading to heightened requirements for robust and efficient electrical solutions. As industries transition towards smart technologies and sustainable practices, the emphasis on high-performance MCCBs, which offer better efficiency, safety, and operational flexibility, will undoubtedly intensify. The growing emphasis on energy conservation and safety standards further supports this trend, positioning high-performance molded case circuit breakers as essential components in future electrical systems across the region.

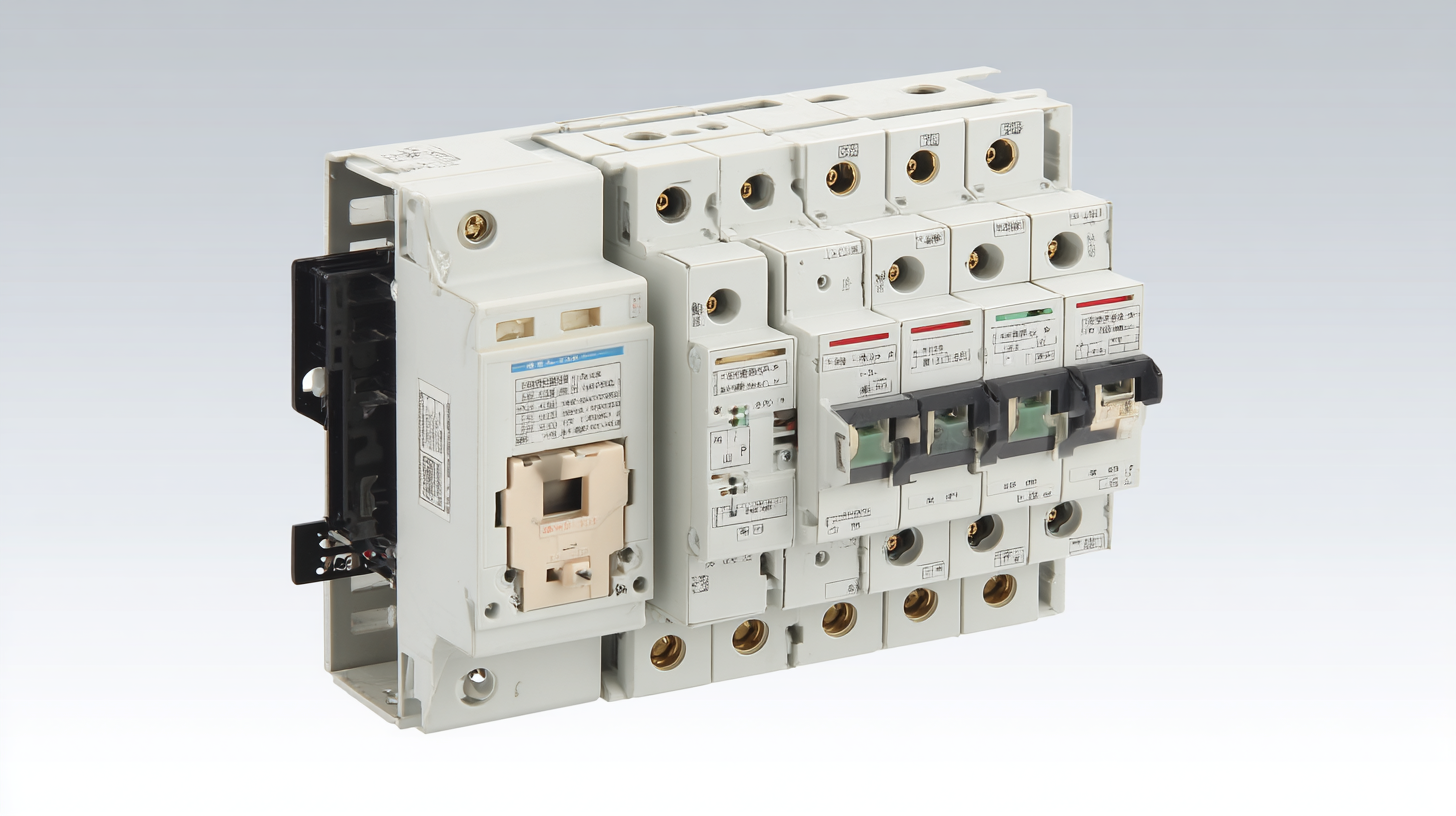

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

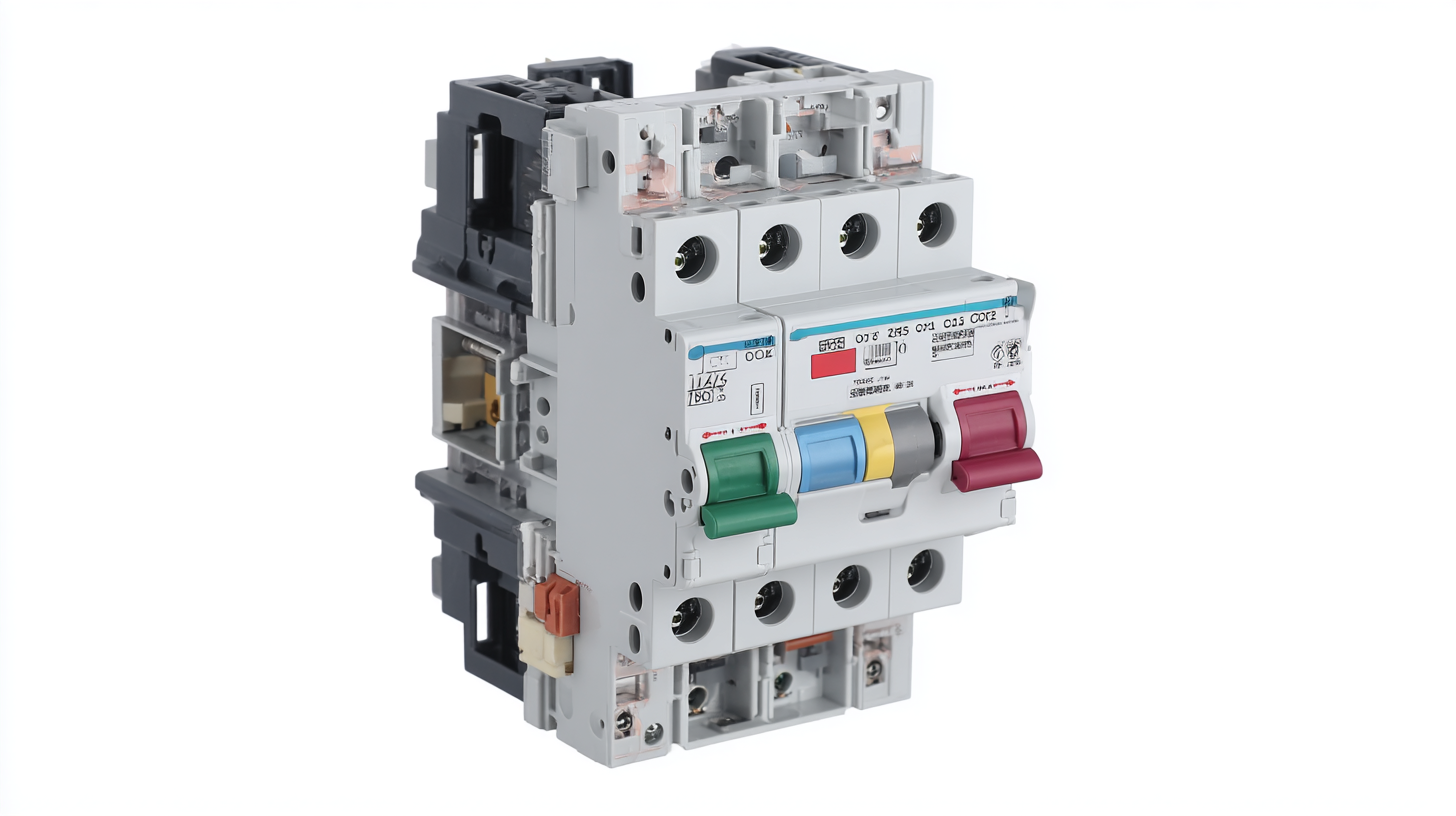

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500