The Future of Power Protection: Exploring Innovations in China Molded Case Circuit Breakers

As the demand for efficient and reliable power protection solutions grows, the China Molded Case Circuit Breaker (MCCB) industry is at the forefront of innovation. According to a recent report by Grand View Research, the global market for MCCBs is expected to reach USD 8.64 billion by 2025, growing at a CAGR of 7.1%. This growth is attributed to the increasing adoption of advanced electrical systems across various sectors, including commercial, industrial, and residential applications. In China, factors such as urbanization, rapid industrialization, and stringent safety regulations are driving the evolution of power protection technologies. Innovative features such as smart monitoring, enhanced fault protection, and improved energy efficiency are becoming standard in the latest MCCBs, which not only address safety concerns but also meet the rising demand for sustainable solutions. This article aims to explore the cutting-edge advancements in China Molded Case Circuit Breakers and their implications for the future of power protection technology.

Innovative Technologies in Molded Case Circuit Breakers in China

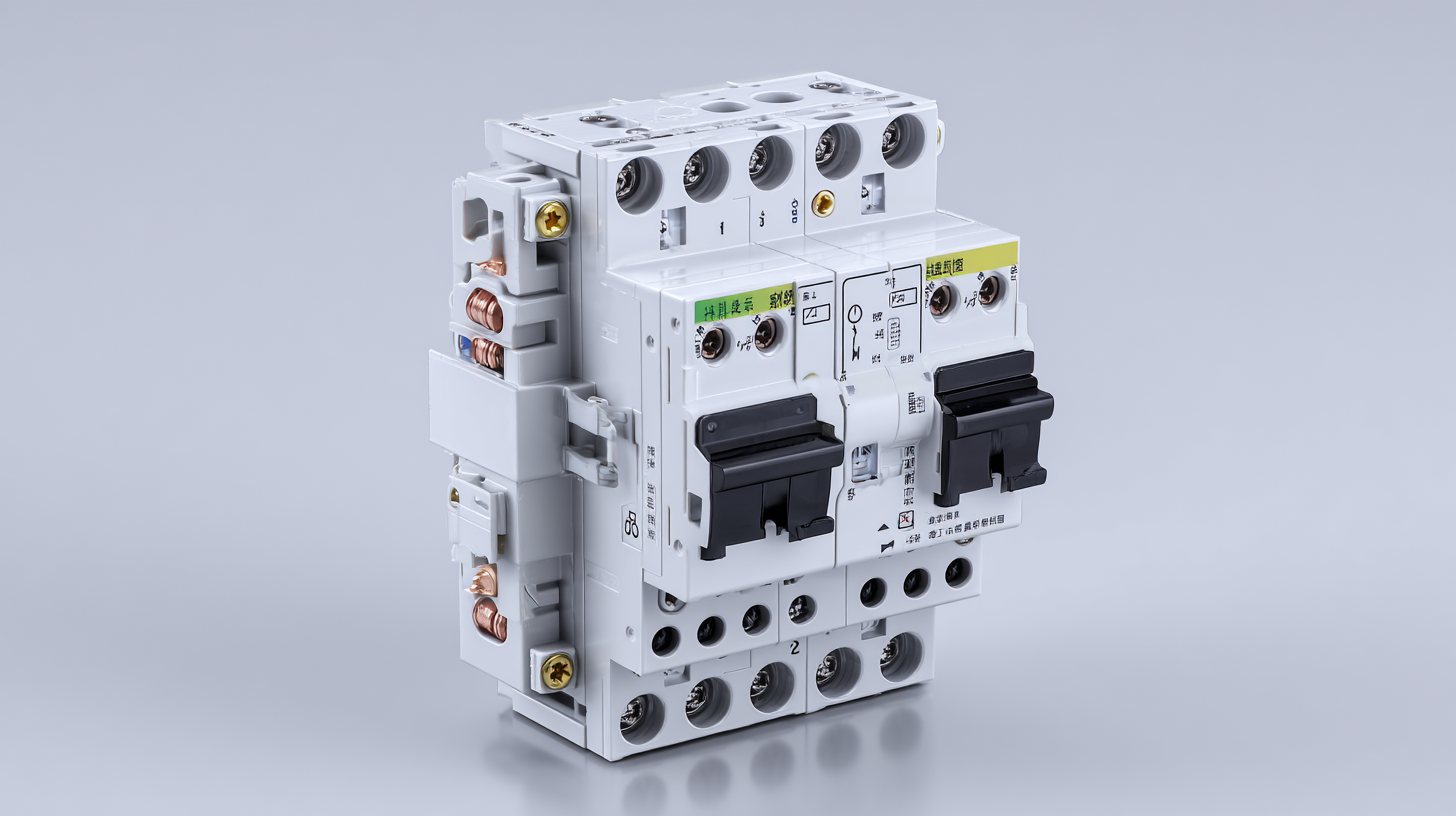

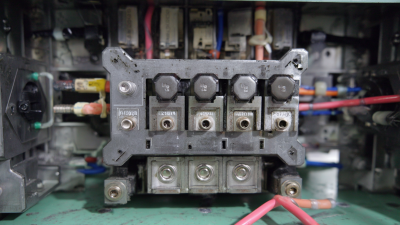

The advancements in molded case circuit breaker (MCCB) technology in China have opened new avenues for power protection solutions. With innovative manufacturing processes and enhanced material quality, Chinese manufacturers are able to produce MCCBs that not only meet but exceed international standards. This evolution is essential, considering the projected growth of the global low voltage DC circuit breaker market, which is expected to reach $2.24 billion by 2032. Such growth rates reflect an increasing demand for reliable and efficient circuit protection solutions.

One of the key innovations in China's MCCB market is the integration of smart technologies. Modern MCCBs are now equipped with digital interfaces that allow for remote monitoring and management, thereby enhancing operational efficiency and safety. This trend aligns with the global emphasis on energy management and sustainability, as seen in related markets like the Battery Energy Storage System (BESS), which is anticipated to experience significant growth in the coming years. The ongoing development of these technologies in China not only strengthens the domestic market but also positions the country as a critical player in the global circuit breaker landscape.

Digital Transformation in Power Protection Solutions

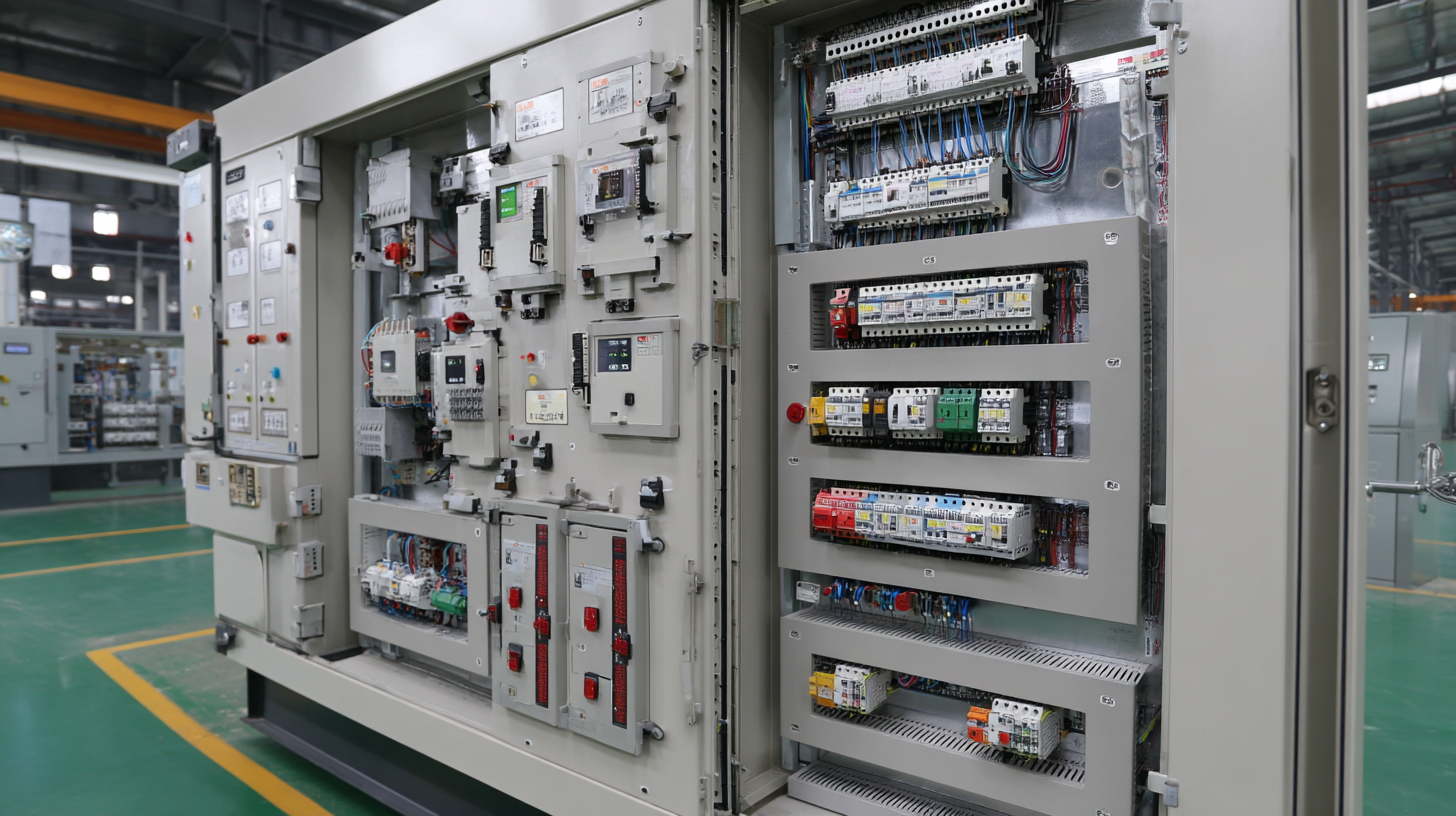

The digital transformation in power protection solutions is revolutionizing the way molded case circuit breakers operate in China. As industries increasingly adopt smart technologies, the integration of digital capabilities in circuit breakers is becoming essential. These innovations enable real-time monitoring and data analytics, allowing for enhanced performance and quicker response times to potential electrical faults. With the Internet of Things (IoT) and artificial intelligence (AI) playing crucial roles, manufacturers are now able to offer predictive maintenance solutions, reducing downtime and minimizing financial losses.

Moreover, digital transformation is fostering greater accessibility and user engagement in power protection. Advanced user interfaces and mobile applications allow operators to monitor power systems remotely, simplifying the management of energy consumption and ensuring compliance with safety regulations. The ability to receive alerts and updates on circuit breaker status enables timely interventions, significantly improving operational efficiency. As China leads the charge in adopting these technologies, the future of molded case circuit breakers promises to be more resilient, intelligent, and adaptable, paving the way for a more reliable power infrastructure.

Smart Features of Modern Circuit Breakers: Enhancing Safety and Efficiency

In recent years, the development of molded case circuit breakers (MCCBs) in China has seen a significant transformation, driven by advanced technologies aimed at enhancing both safety and efficiency. Modern circuit breakers now incorporate smart features such as real-time monitoring, remote diagnostics, and predictive maintenance. According to a recent report by MarketsandMarkets, the global smart circuit breakers market is expected to reach $10.20 billion by 2026, highlighting the growing demand for these innovative solutions.

One of the key benefits of these smart features is improved safety. With integrated sensors and connectivity options, modern MCCBs can detect abnormalities in electrical systems, such as overloads and short circuits, before they lead to catastrophic failures. This proactive approach greatly reduces the risk of electrical fires and equipment damage, aligning with the industry-standard goal of minimizing downtime. A study published by the IEEE indicates that predictive maintenance can reduce maintenance costs by up to 30%, further emphasizing the efficiency gains of these advancements.

**Tips:** When selecting a molded case circuit breaker for your facility, prioritize models that offer connectivity and data analytics capabilities. Additionally, regularly schedule maintenance checks to ensure the smart features function correctly, maximizing your investment in innovative technology. Investing in training for staff on the new systems can also enhance overall operational efficiency.

The Future of Power Protection: Innovations in Molded Case Circuit Breakers

This chart showcases the increasing adoption of smart features in modern molded case circuit breakers (MCCBs) over the years, highlighting their impact on safety and efficiency metrics.

The Role of IoT in Revolutionizing Circuit Breaker Operations

The integration of the Internet of Things (IoT) into circuit breaker operations marks a significant advancement in power protection systems, particularly for molded case circuit breakers (MCCBs) in China. According to a report by MarketsandMarkets, the global IoT in the utility market is expected to grow from $8.8 billion in 2020 to $21.5 billion by 2025, demonstrating the rapid adoption of smart technologies in traditional sectors. In this context, IoT-enabled MCCBs can collect real-time data on electrical parameters, allowing for predictive maintenance and reducing the risk of failures.

The ability of IoT to automate monitoring and control processes is transforming circuit breaker management. Advanced analytics can process data from connected MCCBs to optimize energy usage and enhance operational efficiency. A study by Frost & Sullivan predicts that the implementation of smart circuit breakers could result in a 30% reduction in operational costs for utility companies. Furthermore, remote diagnostics capabilities empower maintenance teams to respond promptly to potential issues, minimizing downtime and enhancing system reliability, which is crucial for preserving the integrity of the electrical grid in urbanizing regions of China.

Future Trends: Sustainable Practices in Power Protection Systems

As the world increasingly emphasizes sustainability, the power protection industry is witnessing a transformative shift. In China, molded case circuit breakers (MCCBs) are evolving not just to enhance electrical safety but also to embrace environmentally friendly practices. Manufacturers are integrating eco-efficient materials and energy-saving technologies into their designs, ensuring that these critical components contribute to a greener energy future. This focus on sustainability paves the way for innovations that not only protect electrical systems but also mitigate their ecological impact.

Moreover, the future trends in power protection systems indicate a growing reliance on smart technologies. Advanced monitoring and predictive maintenance solutions are being developed to optimize the performance of MCCBs while minimizing waste. These innovations enable real-time data analysis, allowing for swift responses to potential issues, thereby reducing downtime and extending the lifespan of electrical systems. The integration of digital tools with sustainable practices illustrates a holistic approach in the energy sector, showcasing how technology and environmental responsibility can work in tandem.

The Future of Power Protection: Exploring Innovations in China Molded Case Circuit Breakers

| Trend | Description | Expected Impact | Sustainability Aspect |

|---|---|---|---|

| Smart Circuit Breakers | Integration of IoT technology for real-time monitoring and management. | Improved energy efficiency and reduced downtime. | Reduction in carbon footprint through optimized energy usage. |

| Eco-Friendly Materials | Use of recyclable and non-toxic materials in manufacturing. | Minimized environmental impact and enhanced product life cycle. | Promotes circular economy principles. |

| Digital Protection Systems | Advanced algorithms for predictive maintenance and fault detection. | Enhanced reliability and reduced operational costs. | Less frequent replacements and lower waste generation. |

| Modular Designs | Flexible configurations allowing for easier upgrades and maintenance. | Cost-effective and scalable solutions for various applications. | Reduction of resource usage by enabling upgrades instead of full replacements. |

| AI Integration | Utilizing artificial intelligence for enhanced decision-making. | Greater accuracy in fault predictions and energy management. | Optimizes energy consumption and reduces greenhouse gas emissions. |

Related Posts

-

Choosing Reliable Manufacturers: Essential Tips and Solutions for Best China Molded Case Circuit Breakers

-

Ultimate Guide to Understanding Molded Case Circuit Breakers for Global Procurement

-

Ultimate Guide to Selecting the Right Air Circuit Breaker for Your Industrial Needs

-

How to Choose the Right Electronic MCCB for Optimal Circuit Protection and Efficiency

-

How to Choose the Right Air Circuit Breaker for Your Electrical System

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500