Navigating Global Compliance: Import and Export Certifications for Best MCCB Moulded Case Circuit Breakers

In today's rapidly evolving global market, understanding compliance regulations for importing and exporting goods is crucial for businesses in the electrical equipment sector, particularly for those dealing with MCCB moulded case circuit breakers. As we approach 2025, the market analysis reveals significant trends and challenges that industry players must navigate to maintain compliance and ensure product quality. This blog aims to explore the various certifications and standards necessary for MCCB moulded case circuit breakers, providing insights into how manufacturers can meet regulatory demands while maximizing their market reach. By examining current market dynamics, international compliance requirements, and effective strategies for certification, we aim to equip stakeholders with the knowledge needed to excel in a competitive landscape.

Understanding the Importance of Import and Export Certifications for MCCB

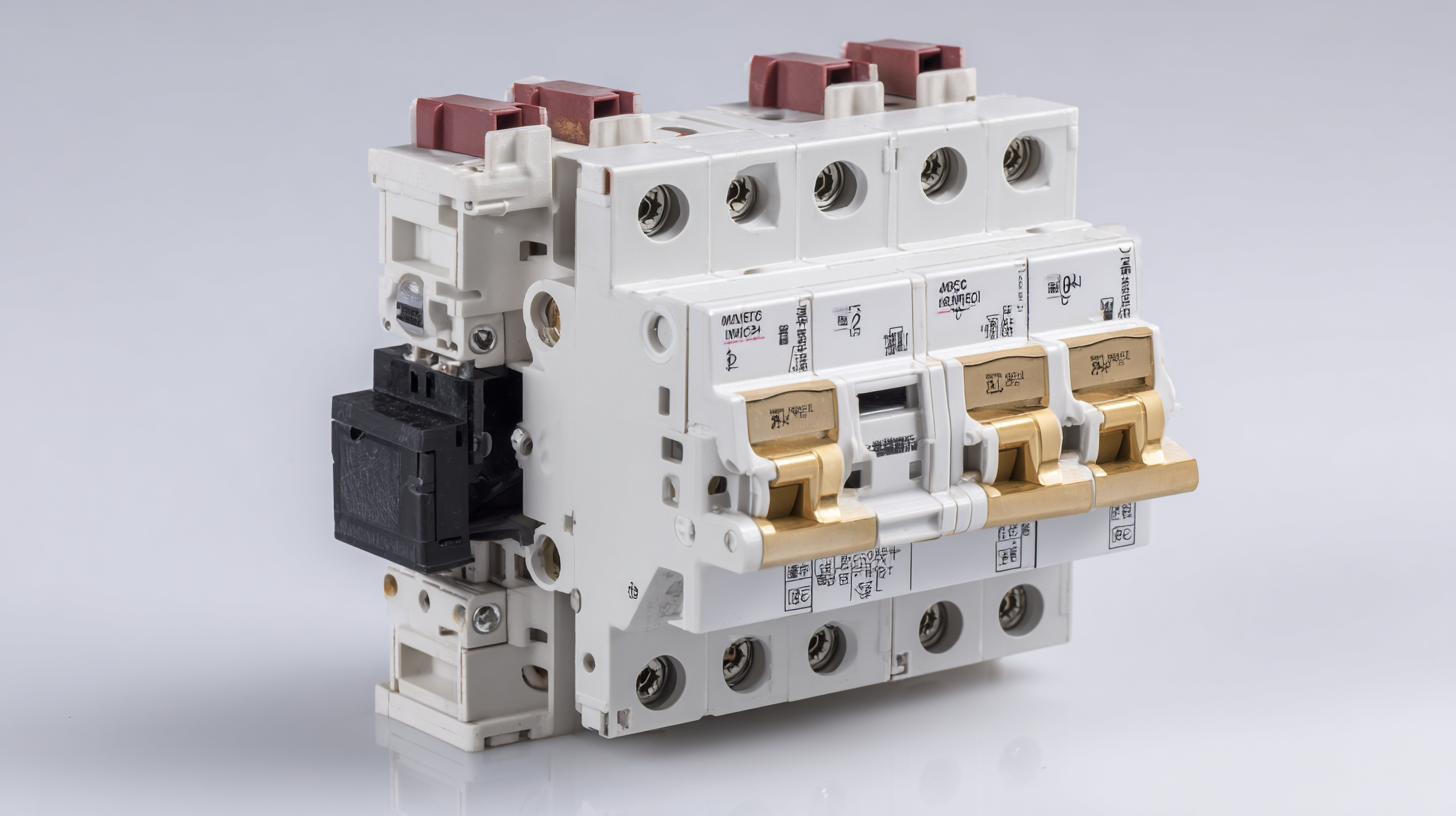

Import and export certifications play a critical role in ensuring the quality and safety of Moulded Case Circuit Breakers (MCCBs), which are essential components in electrical distribution systems. According to a report by MarketsandMarkets, the global MCCB market is projected to reach $10.41 billion by 2025, fueled by increasing industrialization and a rise in infrastructure projects. This growth highlights the importance of adhering to international standards and obtaining the necessary certifications to facilitate cross-border trade.

Understanding the nuances of these certifications is essential for manufacturers looking to penetrate global markets. Certifications such as CE marking in Europe or UL listing in the United States not only enhance product credibility but also ensure compliance with local regulations. A study by TechNavio indicates that companies with recognized certifications can improve their market access and customer trust, which are vital in competitive environments. As such, investing in compliance certifications is not just a regulatory requirement but a strategic advantage in the global MCCB market.

Key Global Compliance Standards for Moulded Case Circuit Breakers

When considering the global market for Moulded Case Circuit Breakers (MCCBs), understanding key compliance standards is essential. Different regions have distinct regulations that dictate how these critical components must be manufactured and tested. For instance, UL 489 is a widely recognized standard in North America, emphasizing safety and performance, while IEC 60947-2 is the corresponding international standard adopted in Europe and other regions. Companies aiming to penetrate markets must ensure that their products meet these standards to avoid penalties and ensure safe operation.

Tips: Always stay updated on the latest compliance regulations in your target markets. Regularly review the necessary certifications, including environmental and safety standards, to ensure your products remain compliant over time. Collaborating with certification bodies can provide valuable insights and facilitate the approval process.

Additionally, investing in thorough testing procedures early in product development can save time and resources. Conducting pre-certification evaluations can help identify potential issues that may arise during official certification, allowing manufacturers to rectify them before they become costly problems. This proactive approach not only strengthens compliance but also enhances product reliability and performance.

Navigating the Certification Process for Exporting MCCBs

Exporting MCCB (Moulded Case Circuit Breakers) requires a keen understanding of global compliance standards and certification processes. To successfully navigate this landscape, manufacturers must first identify the specific certifications required for their target markets. For example, certifications such as UL, CE, or IEC can be critical depending on the region. Each certification comes with its own set of requirements, testing protocols, and documentation, which can vary significantly from one country to another.

Exporting MCCB (Moulded Case Circuit Breakers) requires a keen understanding of global compliance standards and certification processes. To successfully navigate this landscape, manufacturers must first identify the specific certifications required for their target markets. For example, certifications such as UL, CE, or IEC can be critical depending on the region. Each certification comes with its own set of requirements, testing protocols, and documentation, which can vary significantly from one country to another.

Once the required certifications have been identified, companies need to engage with recognized certification bodies to initiate the certification process. This often involves submitting product samples for testing, ensuring that all components meet the stipulated guidelines. Effective communication with certification agencies is crucial to address any compliance concerns early on. Moreover, maintaining meticulous records throughout the process can facilitate a smoother certification journey and enhance the overall credibility of the product. Adhering to these steps not only ensures compliance but also boosts consumer confidence in the safety and reliability of MCCBs in the global market.

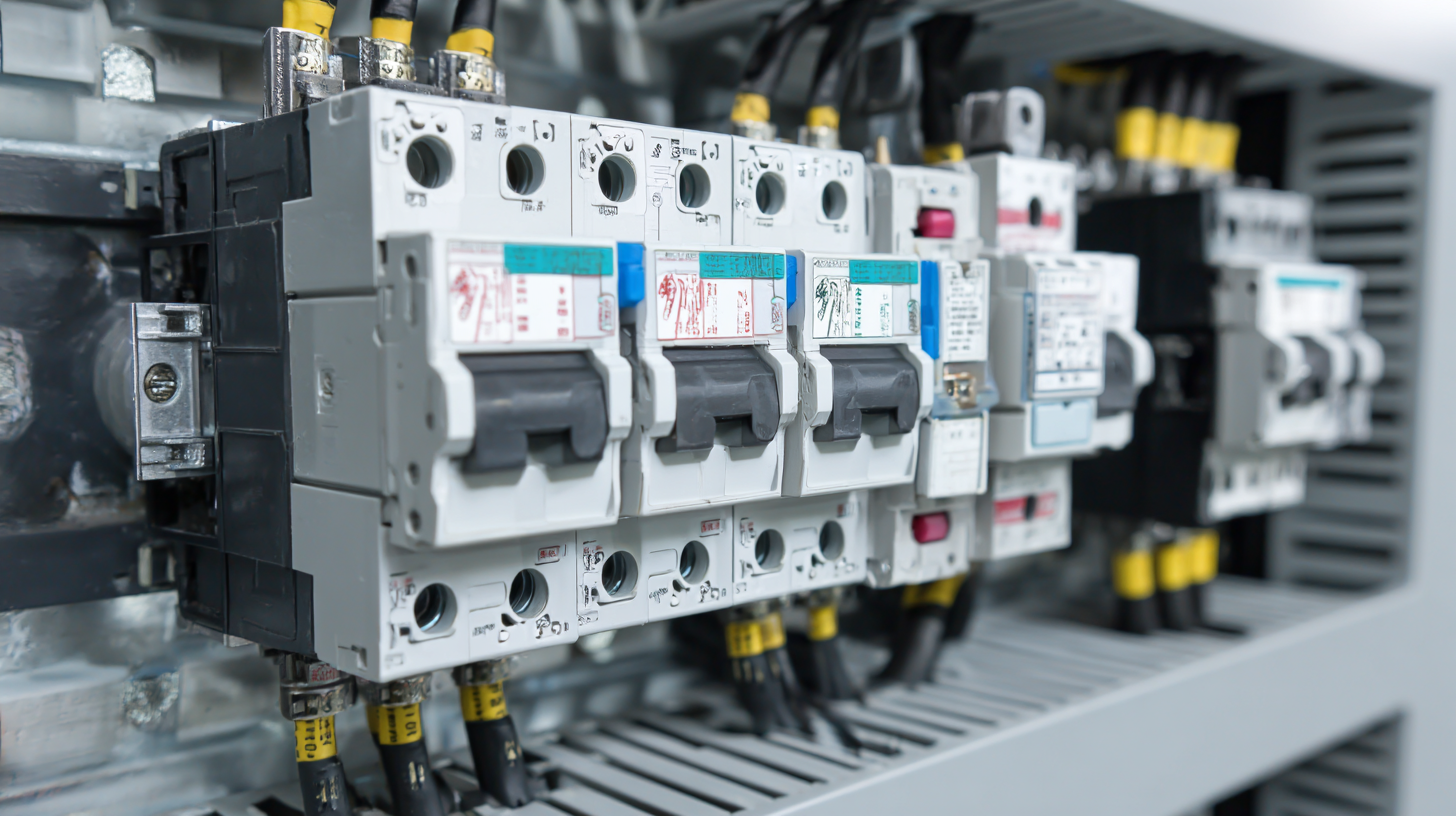

Quality Control: Ensuring Compliance in Manufacturing MCCBs for Global Markets

In the manufacturing sector, ensuring the quality of MCCB (Moulded Case Circuit Breakers) is crucial for meeting global compliance standards. Manufacturers must adhere to rigorous quality control processes that encompass material selection, production techniques, and testing methods. This commitment not only guarantees product integrity but also builds customer trust in international markets.

Implementing strict quality control measures helps organizations avoid costly recalls and maintains their reputation among industry players.

To enhance compliance in manufacturing, consider these tips:

- Conduct regular audits of your production processes to identify potential areas for improvement. Implementing a continuous feedback loop can significantly enhance product quality over time.

- Invest in staff training on the latest compliance regulations and quality control techniques. Educated employees are better equipped to maintain standards and recognize compliance issues before they become problematic.

Lastly, utilize advanced technologies such as automated testing equipment to ensure that each MCCB meets the necessary certifications. Automation can increase efficiency and accuracy in verifying that all products conform to specific regulatory requirements. By prioritizing quality control in the manufacturing of MCCBs, companies can successfully navigate the complexities of global compliance.

The Role of Chinese Manufacturing in Global MCCB Markets and Certifications

China's role in the global MCCB market is increasingly significant, particularly as it pertains to compliance certifications. As countries like Sri Lanka integrate advanced electrical solutions, the need for high-quality, certified products becomes paramount. For instance, the growth of the MCCB market is projected to expand at a CAGR of approximately 6.5% from 2020 to 2025, driven by rising infrastructural developments in emerging economies. The importance of obtaining local certifications, such as the SLS certification in Sri Lanka, cannot be overstated, as these credentials not only validate product safety and reliability but also facilitate smoother market entry.

Chinese manufacturers are stepping up to meet these demands, adapting their products to comply with widespread international standards. The influx of companies entering new markets mirrors a rising trend in globalization, where localized compliance is essential for market success. The ability to navigate stringent certification processes enables manufacturers to cater to diverse regulatory environments effectively.

Recent entries into markets like Sri Lanka showcase the importance of aligning product offerings with local compliance requirements, ensuring that manufacturers maintain their competitive edge while upholding quality and safety standards. With over 70% of the global MCCB supply relying on imports, understanding and adapting to these certification requirements is vital for sustaining growth and meeting international market needs.

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500