Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

In the ever-evolving landscape of electrical components, selecting the right Molded Case Breaker (MCB) has become crucial for ensuring safety and efficiency in both residential and industrial applications. According to a recent market research report by Grand View Research, the global molded case circuit breaker market is expected to reach $6.6 billion by 2025, growing at a CAGR of 6.2% from 2019 to 2025. This growth is driven by the increasing demand for reliable power distribution and safety solutions in various sectors.

With numerous manufacturers offering a variety of MCBs, it's essential to understand the key factors in choosing a quality manufacturer, including compliance with international standards, innovative technology, and proven performance in diverse environmental conditions. This blog will delve into the ultimate techniques for selecting the best Molded Case Breaker, ensuring that you make an informed choice in today’s competitive market.

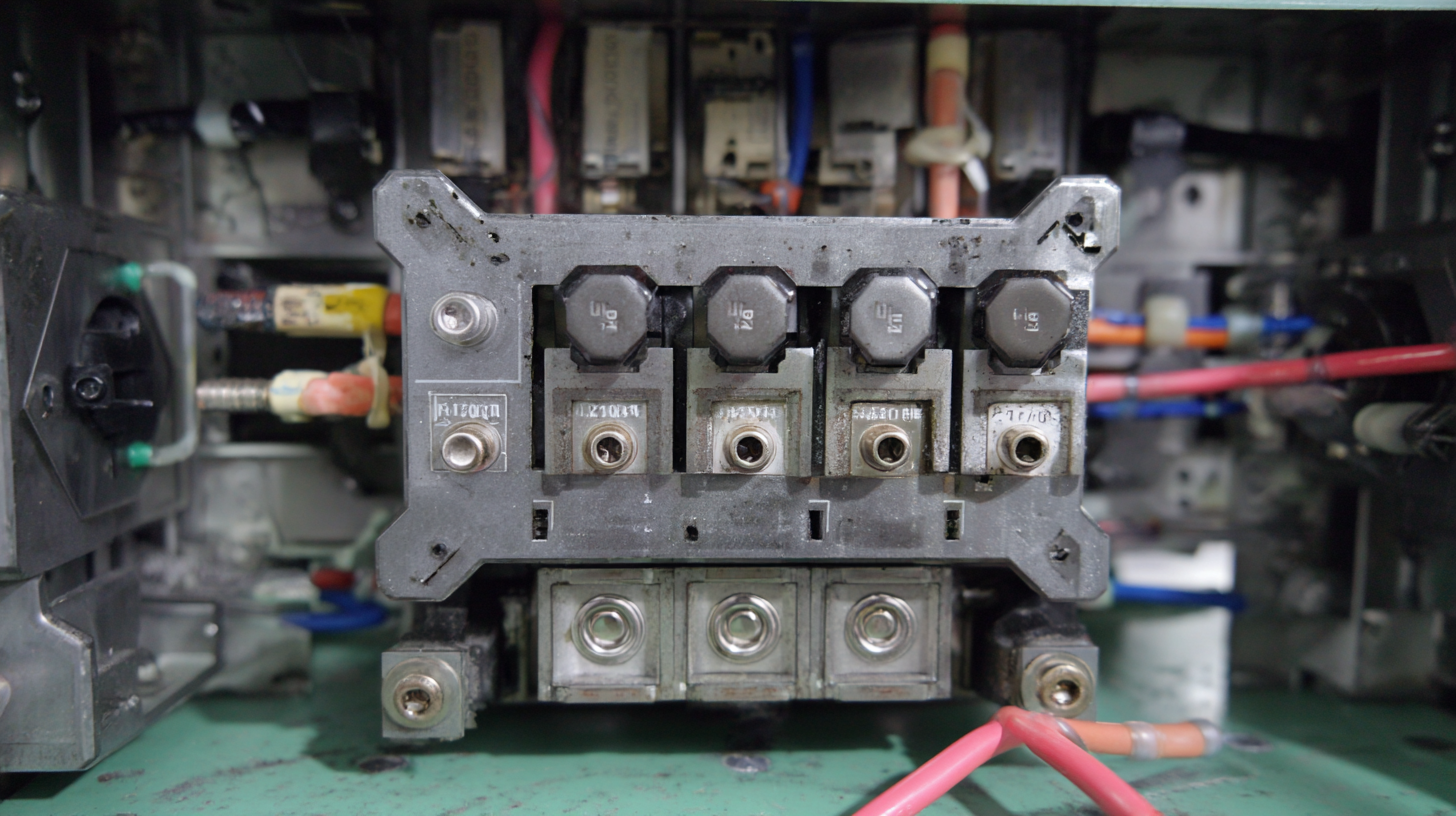

Understanding Molded Case Breakers and Their Applications in Modern Industries

Molded case breakers (MCBs) are essential components in modern electrical systems, providing protection against overloads and short circuits. These devices are designed to detect electrical faults and disconnect the circuit, thereby preventing potential hazards like fires and equipment damage. Their versatility makes them suitable for various applications, ranging from residential buildings to large industrial plants. Understanding the specific requirements of each application is crucial when selecting the right MCB.

In industrial settings, MCBs are often employed in critical operations involving heavy machinery and complex electrical networks. They not only safeguard equipment but also ensure compliance with safety regulations. Additionally, advancements in technology have led to the development of smart molded case breakers that offer enhanced monitoring capabilities. These innovations allow industries to track performance data, facilitating proactive maintenance and reducing downtime. Whether it’s for commercial infrastructure or sophisticated production lines, choosing the appropriate molded case breaker is vital for enhancing safety and operational efficiency.

Key Factors to Consider When Choosing a Molded Case Breaker

When choosing the best molded case breaker, several key factors should be at the forefront of your decision-making process. First and foremost, consider the application requirements of your electrical system. It’s essential to assess the load characteristics, including current ratings and voltage levels, to ensure that the breaker can handle specific demands safely and efficiently. Additionally, understanding the difference between thermal-magnetic and electronic trip mechanisms can aid in selecting a product that offers the right level of protection and trip sensitivity for your needs.

Another critical factor is the breaker’s physical configuration and compatibility with your existing electrical infrastructure. Evaluate the dimensions and mounting options to ensure a seamless installation. Furthermore, examining the manufacturer’s reputation and product warranties can provide insights into the reliability and longevity of the molded case breakers available on the market. By focusing on these key factors, you can make a well-informed choice that guarantees optimal performance and safety for your electrical systems.

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market - Key Factors to Consider When Choosing a Molded Case Breaker

| Key Factor | Description | Importance Level |

|---|---|---|

| Current Rating | Determines the maximum load the breaker can handle without tripping. | High |

| Breaking Capacity | The maximum short-circuit current that the breaker can interrupt. | High |

| Trip Mechanism | The technology used to trip the breaker during overload or fault conditions. | Medium |

| Size and Form Factor | Physical dimensions and configuration that affect installation requirements. | Medium |

| Environmental Ratings | Protection against dust, water, or hazardous conditions. | High |

| Cost | Total price of the breaker, including installation costs. | Medium |

| Regulatory Compliance | Adherence to local and international safety and performance standards. | High |

Emerging Technologies Impacting Molded Case Breaker Design and Functionality

Emerging technologies are dramatically reshaping the design and functionality of molded case breakers (MCBs). Advanced materials, such as high-performance plastics and composites, are being utilized to enhance the durability and thermal performance of MCBs, making them more reliable in demanding environments. Additionally, the integration of smart technology allows for real-time monitoring and diagnostics, enabling predictive maintenance and reducing downtime.

When selecting an MCB in today’s market, consider the compatibility of these emerging technologies with your existing systems. Look for breakers that offer connectivity features, such as IoT integration, allowing you to gather performance data and maintenance alerts. This not only improves operational efficiency but also ensures that you can respond swiftly to any potential issues, minimizing risks.

Another important tip is to pay attention to energy efficiency. Innovative design features that reduce energy losses can contribute to lower operational costs over time. Seek out MCBs that incorporate energy-saving technologies and are compliant with international efficiency standards, ensuring that your selection not only meets performance criteria but also supports sustainability goals.

Comparative Analysis of Leading Molded Case Breaker Brands

When selecting the best molded case breaker (MCB) in today’s competitive market, it is essential to conduct a thorough comparative analysis of the leading brands. According to a recent industry report by Market Research Future, the molded case circuit breaker market is expected to grow at a CAGR of 6.1% from 2022 to 2028, highlighting the increasing demand for reliable and efficient electrical protection devices. Key players such as Schneider Electric, Siemens, and ABB dominate the market, each offering unique features and advancements that cater to varying customer needs.

Schneider Electric, for instance, is known for its EcoStruxure technology, which integrates MCBs into a broader network for smarter energy management. In contrast, Siemens focuses on compact designs without compromising on performance efficiency. Their SIRIUS series boasts impressive space-saving capabilities alongside robust protection standards.

Meanwhile, ABB's innovative braking technology is expected to enhance power system resilience, pushing their market share higher as reported in a 2023 electrical equipment analysis. By understanding the strengths and weaknesses of these leading brands, consumers can make informed decisions that align with their operational requirements and budget constraints.

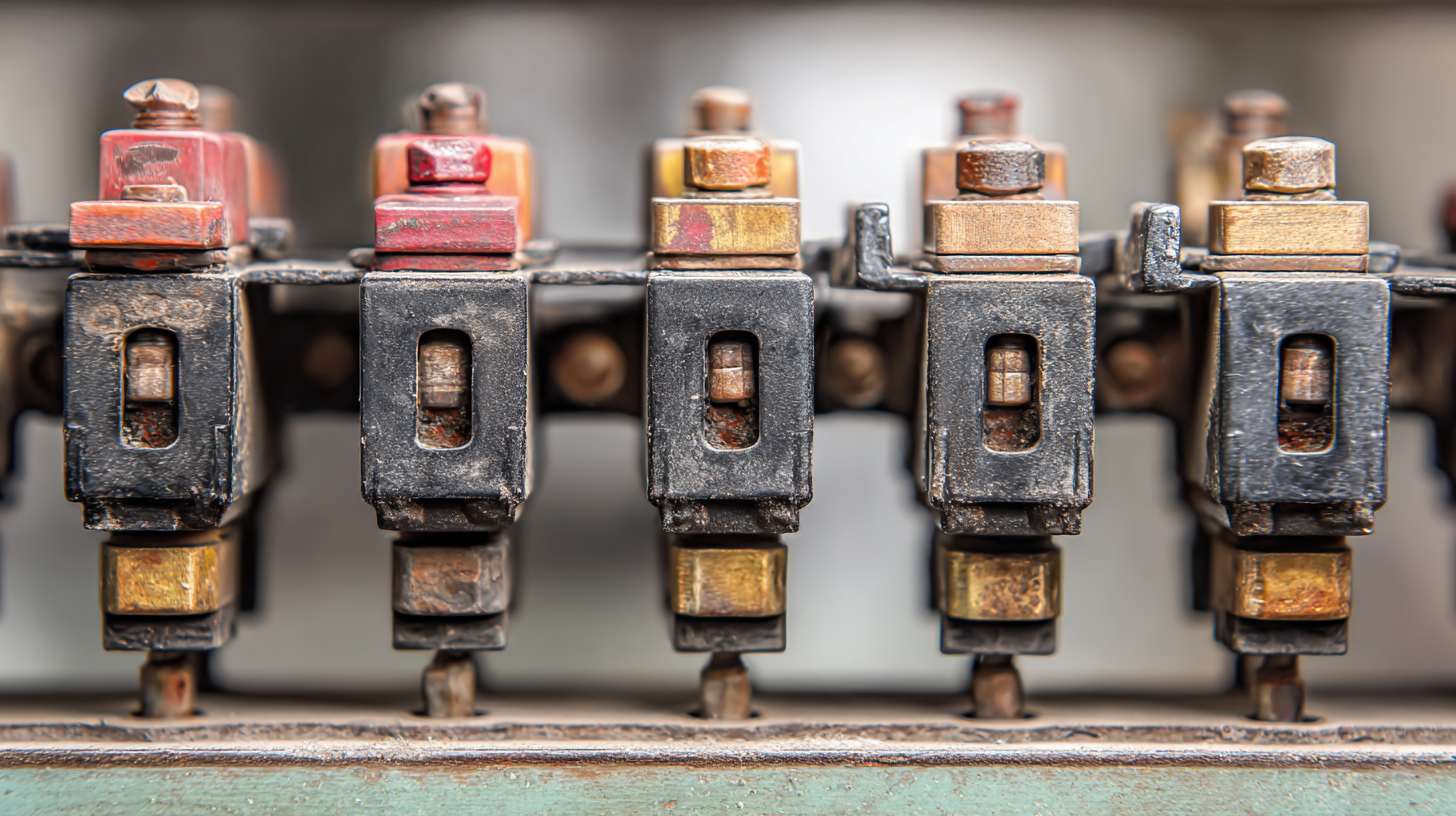

Best Practices for Maintenance and Optimization of Molded Case Breakers

When it comes to ensuring the longevity and efficiency of molded case breakers (MCBs), adherence to best maintenance practices is essential. According to a recent report by the International Electrotechnical Commission (IEC), proper maintenance can increase the lifespan of electrical equipment by up to 30%. Regular inspections and service checks not only help in identifying potential issues but also ensure that the breakers are responding correctly to overloads and short circuits, integral for safety in electrical systems.

One key optimization practice involves periodic thermal imaging, which can detect hot spots that may indicate impending failures. The National Fire Protection Association (NFPA) highlights that electrical faults lead to over 30,000 home fires annually; thus, proactive maintenance can significantly reduce risk and enhance reliability. Additionally, cleaning and tightening connections can prevent corrosion and ensure efficient electrical flow, contributing to the overall effectiveness of the MCBs. By prioritizing these maintenance strategies, businesses can not only comply with industry standards but also safeguard their investments in electrical infrastructure.

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500