The Ultimate Guide to Understanding China Molded Case Circuit Breakers and Their Applications

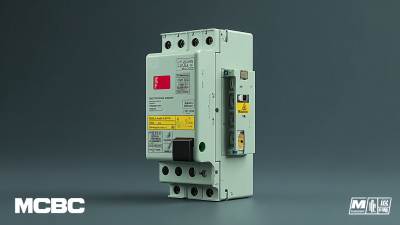

In the realm of electrical safety and power management, the China Molded Case Circuit Breaker (MCCB) stands out as a crucial component in safeguarding electrical circuits from overloads and short circuits. This guide aims to provide a comprehensive understanding of the various types, features, and applications of MCCBs manufactured in China, which are increasingly favored for their reliability and innovative designs.

From industrial applications to residential use, the China Molded Case Circuit Breaker plays a significant role in ensuring efficient power distribution and protection mechanisms. Whether you are an engineer, electrician, or a homeowner looking to enhance your electrical systems, this guide will offer valuable insights and practical tips to navigate the complexities of choosing the right MCCB for your needs.

Join us as we delve into the essential facts and tips that will empower you to make informed decisions regarding these indispensable safety devices.

Understanding the Basics of Molded Case Circuit Breakers in China

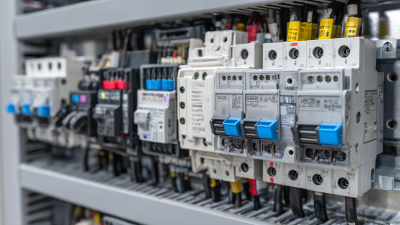

Molded case circuit breakers (MCCBs) are essential components in electrical systems, serving as a protective device that prevents overloads and short circuits. In China, these devices are gaining prominence due to the country’s rapid industrialization and the increasing demand for reliable electrical safety measures. Understanding the fundamentals of MCCBs is crucial for engineers and technicians working in various sectors, from manufacturing to commercial facilities.

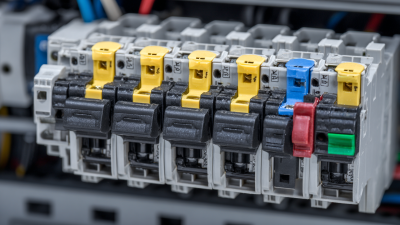

In China, MCCBs are designed to comply with both national and international standards, ensuring safety and efficiency. They come in various sizes and configurations, making them suitable for a wide range of applications, including motor control, lighting, and power distribution. The modular design of these breakers allows for easy integration into existing electrical systems, enhancing their overall functionality. Moreover, advancements in technology have led to the development of digital MCCBs, which provide smart features such as remote monitoring and integration with building management systems, offering greater flexibility and control over electrical resources.

Key Components and Features of China Molded Case Circuit Breakers

Molded case circuit breakers (MCCBs) are vital components within electrical systems, designed to protect circuits from overcurrents and short circuits. Key features of MCCBs include thermal and electromagnetic trip mechanisms, which ensure reliable disconnection in fault conditions. Furthermore, their compact design allows for installation in a variety of settings, accommodating both residential and industrial applications. Understanding these key components is essential for selecting the right MCCB for specific operational needs.

Tips: When choosing an MCCB, consider the voltage ratings, current-carrying capacity, and specific application requirements to ensure optimal performance. Regular inspection and maintenance of these devices can significantly enhance their operational life and reliability.

The growing global demand for advanced electrical safety equipment is reflected in the market trends for circuit breakers, including MCCBs. As industries increasingly adopt innovative technologies, the capability for condition assessment using data-driven methods like back propagation neural networks offers promising advancements. This approach enables real-time monitoring and predictive maintenance, ensuring that MCCBs function effectively throughout their operational lifespan.

The Ultimate Guide to Understanding China Molded Case Circuit Breakers

Applications of Molded Case Circuit Breakers in Various Industries

Molded case circuit breakers (MCCBs) play a vital role across various industries by providing reliable protection against overloads and short circuits. Their applications span residential, commercial, and industrial sectors, where they are integral to managing electrical safety and equipment functionality. In industrial settings, MCCBs are employed to safeguard critical machinery, ensuring operational continuity while complying with stringent safety standards. Their versatility in handling different current ratings allows them to cater to a wide range of power requirements, making them essential in manufacturing, construction, and energy distribution industries.

The market for molded case circuit breakers is projected to experience significant growth, particularly in North America, where it is expected to reach approximately $2.19 billion by 2030. This growth is driven by an increasing demand for advanced circuit protection solutions that enhance energy efficiency and reliability. Industries are continuously seeking upgraded technologies that can not only manage electrical loads but also provide smarter control capabilities. As companies in various sectors invest in modern electrical infrastructure, the adoption of MCCBs is set to rise, reflecting their critical role in ensuring safety and efficiency in power management.

Selecting the Right Molded Case Circuit Breaker for Your Needs

When selecting the right molded case circuit breaker (MCCB) for your needs, it's crucial to consider several factors that ensure safety and efficiency in your electrical systems. Start by determining the required current rating based on the appliances and equipment you intend to use. It’s also important to assess environmental conditions, as factors like temperature and humidity can influence the performance of the MCCB. Additionally, consider the breaking capacity of the breaker to ensure it can handle potential short circuits without damaging connected devices.

Tips: Always check the manufacturer's specifications and ensure that the MCCB conforms to relevant safety standards. It's helpful to consult with an electrical engineer or a qualified technician to evaluate your specific needs accurately, especially if your setup includes specialized machinery or high-load systems.

Another important aspect is to be aware of the operational characteristics of the MCCB you choose. For example, thermal-magnetic breakers are ideal for general use, while electronic breakers offer advanced features like adjustable trip settings and remote monitoring capabilities. Understanding these distinctions will help you select a breaker that not only meets your current demands but also accommodates future expansions or upgrades.

Tips: Don't overlook the importance of maintenance and periodic testing of your MCCB system to ensure reliability and longevity. Regular inspections can prevent unexpected failures and enhance overall system performance.

Maintenance and Troubleshooting Tips for Molded Case Circuit Breakers

Maintaining molded case circuit breakers (MCCBs) is essential for ensuring the reliability and safety of electrical systems. One critical aspect is regularly checking the adjustable trip settings, as improper adjustments can lead to unnecessary downtime or even equipment failure. Adopting a proactive maintenance strategy can significantly enhance the performance of MCCBs. Additionally, it is crucial to ensure that breakers are easily accessible for inspections and any necessary servicing. Front-accessible designs facilitate timely maintenance, minimizing the risks associated with electrical switchgear downtime.

Troubleshooting MCCBs can often be straightforward if proper procedures are followed. Conducting routine visual inspections can help identify potential issues before they escalate. Involving advanced equipment can improve diagnostic capabilities, allowing for quick pinpointing of faults. Moreover, training staff on basic troubleshooting techniques enhances the safety and operational efficiency of switchgear, ensuring that any problems can be swiftly addressed without extensive delays. By integrating these maintenance and troubleshooting tips, organizations can safeguard their electrical systems and maintain continuous operations.

Related Posts

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

-

Unlocking Opportunities: Microprocessor Based MCCB Market Trends at the 138th Canton Fair 2025

-

How to Choose the Right Electronic MCCB for Optimal Circuit Protection and Efficiency

-

Understanding Industry Standards and Challenges in Sourcing the Best Lsig Circuit Breaker Globally

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

Ultimate Checklist for Choosing the Best Low Voltage Circuit Breaker

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500