Exploring the Unique Features and Applications of Best Thermal Magnetic Circuit Breakers with Practical Usage Tips

In the realm of electrical engineering, the Thermal Magnetic Circuit Breaker stands as a crucial component, combining both thermal and magnetic protection to safeguard electrical systems from overloads and short circuits. According to the latest industry reports, the global circuit breaker market is projected to reach USD 14.37 billion by 2026, growing at a CAGR of 7.6% from 2021 to 2026. This growth is driven by increasing investments in renewable energy and industrial automation, highlighting the importance of reliable protection solutions like Thermal Magnetic Circuit Breakers. Their unique features, such as the ability to detect varying fault currents while providing reliable thermal protection, make them indispensable in modern electrical applications. In this blog, we will delve into the distinctive characteristics and practical usage tips for maximizing the efficiency and reliability of Thermal Magnetic Circuit Breakers in various environments.

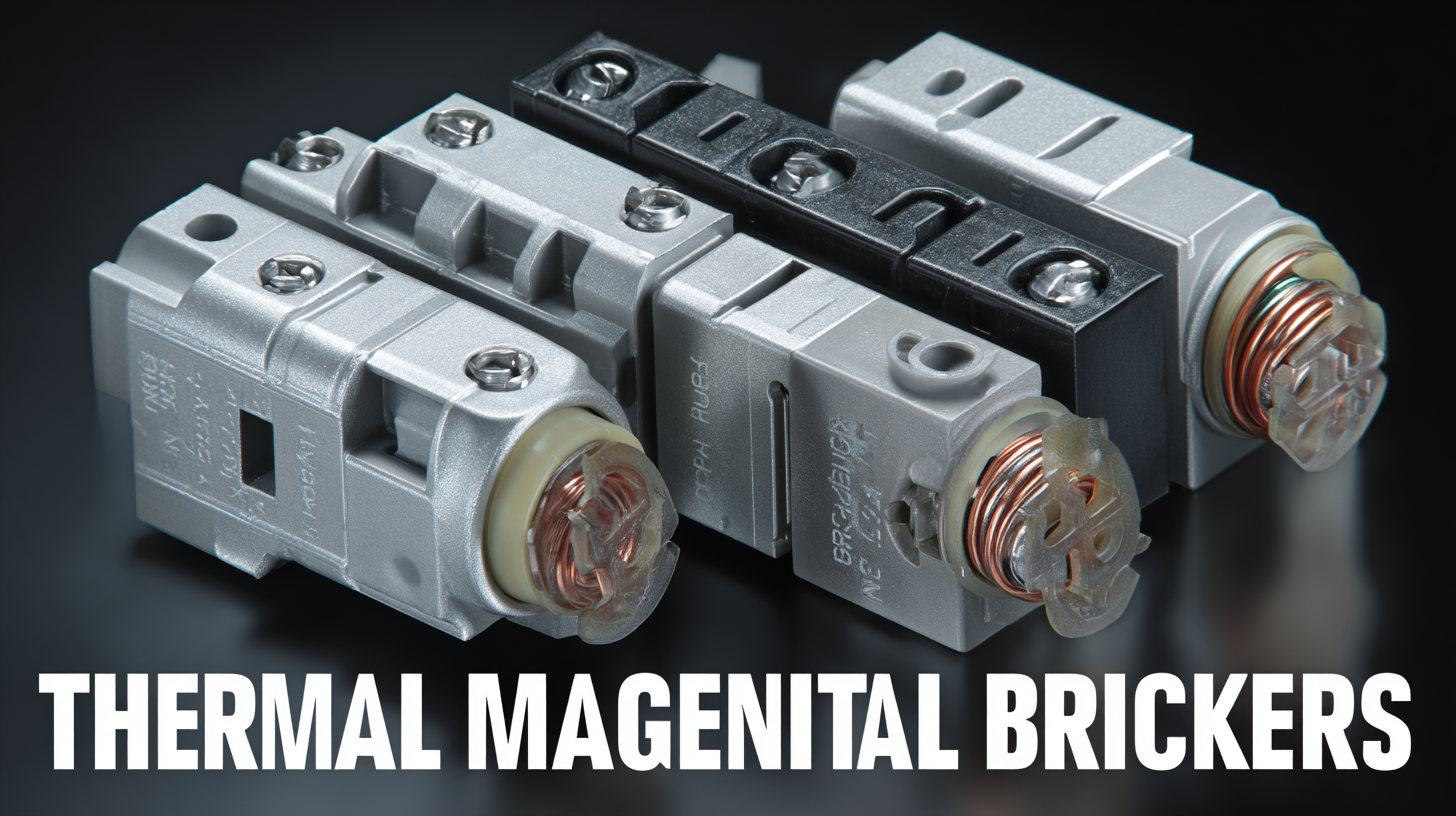

Unique Design Elements of Thermal Magnetic Circuit Breakers

Thermal magnetic circuit breakers combine two key technologies to provide superior protection against overloads and short circuits, making them essential components in electrical systems. The unique design features of these breakers include an electromechanical mechanism that detects overcurrents and an adjustable trip setting, which allows users to customize the level of protection based on their specific applications. According to the International Electrotechnical Commission, thermal magnetic circuit breakers can withstand up to 10,000 amperes of fault current, ensuring a high level of reliability in various environments.

When selecting a thermal magnetic circuit breaker, consider the load type and installation environment. Specifically, for residential and commercial applications where the load may fluctuate, look for breakers with adjustable trip settings that can adapt to changing conditions. It’s also beneficial to choose models that comply with the latest safety standards, such as IEC 60947-2, as these provide an added layer of assurance regarding performance and safety.

Tip: Regular maintenance of your circuit breakers is crucial. Performing periodic inspections can help identify potential issues before they lead to system failures. Ensure that the connections are tight and free from corrosion, as this can significantly impact the performance of your thermal magnetic circuit breakers.

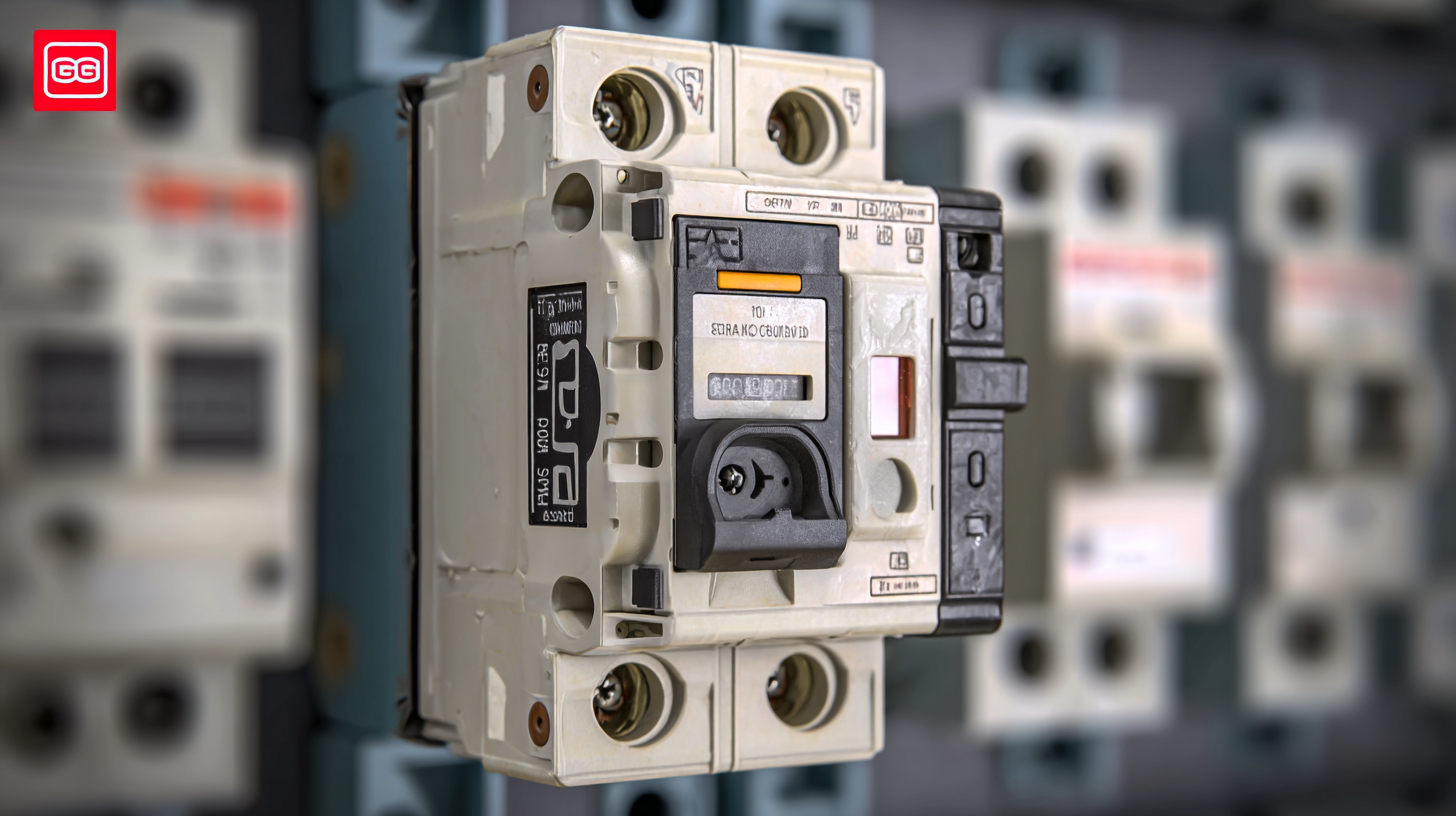

Key Applications in Residential and Industrial Settings

Thermal magnetic circuit breakers are essential components in both residential and industrial settings, providing critical protection against overloads and short circuits. In residential applications, the National Fire Protection Association (NFPA) reports that electrical faults are responsible for nearly 50,000 structure fires annually. Thermal magnetic circuit breakers mitigate these risks by combining the thermal element for overload protection with a magnetic mechanism for instantaneous short-circuit protection. This dual-action ensures that most common residential electrical issues are handled promptly, safeguarding both property and lives.

In industrial environments, the demands for efficient and reliable circuit interruption are even higher. According to a report from the International Electrotechnical Commission (IEC), industrial electrical systems face a 30% higher risk of faults due to the complexity of machinery and equipment. Here, thermal magnetic circuit breakers serve a crucial role in system stability and worker safety by limiting the damage caused by electrical failures. Implementing these breakers helps industries comply with safety standards while enhancing operational efficiency. Understanding their unique features and applications can lead to better decision-making when selecting the right circuit protection for various environments.

Exploring the Unique Features and Applications of Best Thermal Magnetic Circuit Breakers with Practical Usage Tips

| Feature | Description | Application Area | Usage Tips |

|---|---|---|---|

| Thermal Protection | Prevents overheating by tripping based on current and time. | Residential wiring circuits | Regularly inspect for wear and tear on wiring. |

| Magnetic Protection | Provides instantaneous tripping during short circuits. | Industrial machinery | Configure rating based on equipment specifications. |

| Adjustable Settings | Allows customization of trip settings according to load requirements. | Commercial buildings | Regularly update settings to match changing loads. |

| Compact Design | Space-saving design suitable for various installations. | Panel boards | Ensure proper ventilation around breakers. |

| Multiple Poles | Available in single, double, and three-pole configurations. | Residential and industrial electrical systems | Choose appropriate pole configuration for specific applications. |

Practical Tips for Optimal Usage and Maintenance

Thermal magnetic circuit breakers are essential components in electrical systems, providing both overcurrent protection and overload management. Understanding their optimal usage and maintenance can significantly enhance their performance and lifespan. According to a report by the National Electrical Manufacturers Association, improper maintenance can lead to a failure rate of up to 15%, highlighting the importance of regular inspections and upkeep.

One practical tip for optimal usage is to ensure proper sizing of the circuit breaker for your application. The International Electrotechnical Commission (IEC) recommends that circuit breakers be rated based on load characteristics and environmental factors. Overloading a breaker can lead to nuisance tripping or potential damage, so it’s crucial to select one that matches the specific demands of your electrical load.

Regularly testing the functionality of your circuit breakers is another essential maintenance step. The American National Standards Institute (ANSI) suggests performing periodic inspections and functional tests at least once every six months. This helps in identifying any potential issues early on, ensuring that the circuit breakers operate effectively when needed. Implementing these tips will not only extend the lifespan of your thermal magnetic circuit breakers but also enhance the overall safety of your electrical system.

Comparative Analysis: Thermal Magnetic vs. Other Breaker Types

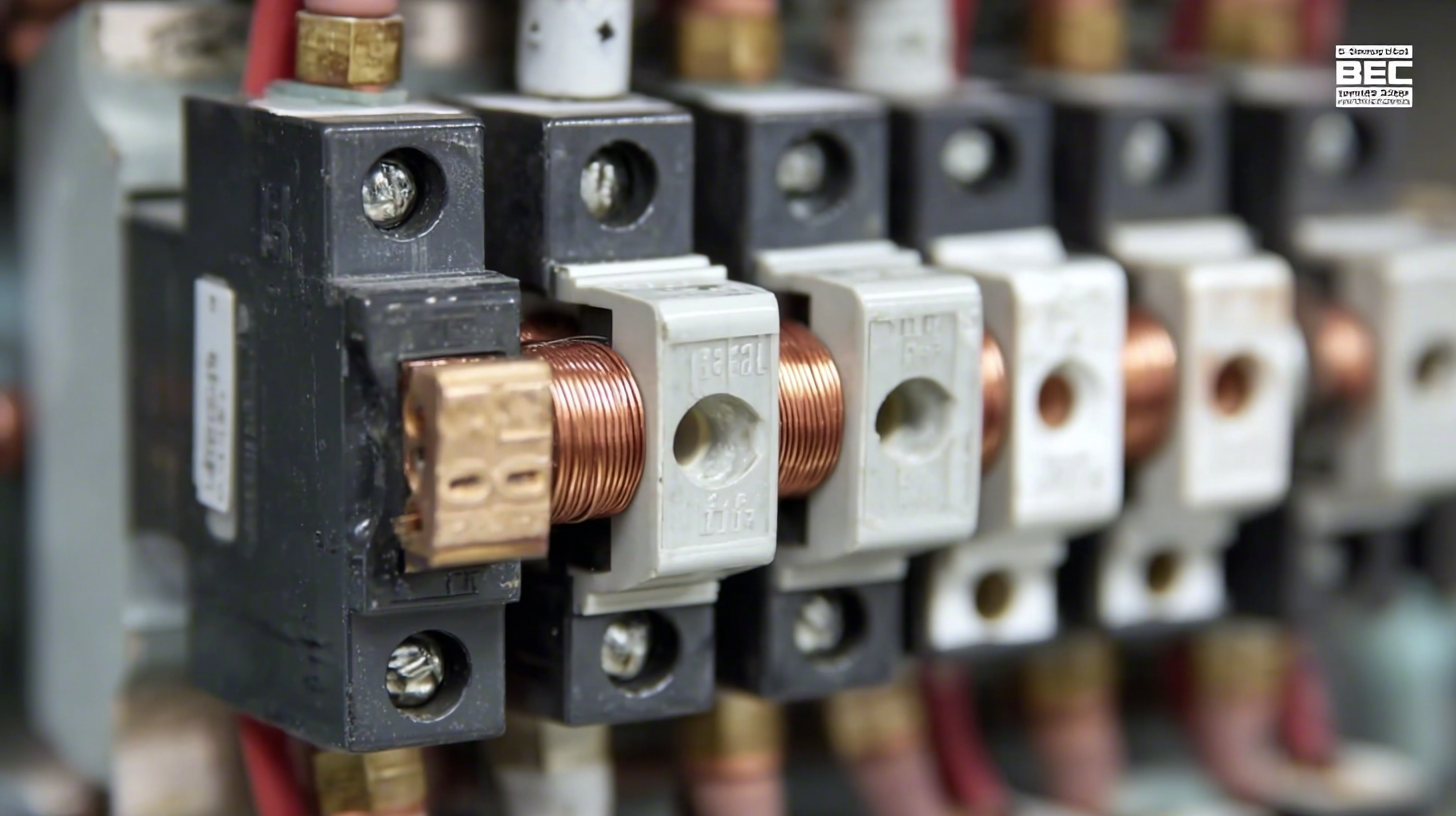

Thermal magnetic circuit breakers are versatile devices that combine the benefits of both thermal and magnetic protection. Unlike standard circuit breakers, which may rely on one principle of operation, thermal magnetic breakers offer a two-in-one solution. This enables them to handle both overloads and short circuits effectively, making them suitable for various applications—from household electrical systems to industrial machinery. Their ability to react to different types of electrical faults allows for enhanced safety and greater system reliability.

Thermal magnetic circuit breakers are versatile devices that combine the benefits of both thermal and magnetic protection. Unlike standard circuit breakers, which may rely on one principle of operation, thermal magnetic breakers offer a two-in-one solution. This enables them to handle both overloads and short circuits effectively, making them suitable for various applications—from household electrical systems to industrial machinery. Their ability to react to different types of electrical faults allows for enhanced safety and greater system reliability.

When comparing thermal magnetic circuit breakers to other types, such as electronic or hydraulic magnetic breakers, their simplicity in design and functionality stands out. Thermal magnetic breakers are generally more robust, providing a reliable protection mechanism without the need for complex electronic components. This leads to a longer lifespan and easier maintenance. However, they may not offer some of the advanced features found in electronic breakers, like adjustable trip settings or the ability to monitor electrical parameters.

Here are some practical tips for using thermal magnetic circuit breakers: Firstly, ensure that the breaker is correctly rated for your specific voltage and current requirements to prevent nuisance tripping. Additionally, keep the breaker properly labeled and understand its operation—many operational issues can be mitigated through regular monitoring. Lastly, if you're experiencing frequent trips, consider consulting a professional to assess if there may be underlying electrical issues that need addressing.

Safety Standards and Regulations Impacting Circuit Breakers

When it comes to thermal magnetic circuit breakers, compliance with safety standards and regulations is paramount. The National Electrical Code (NEC) and International Electrotechnical Commission (IEC) guidelines highlight the importance of selecting breakers that meet specific performance standards to ensure residential and industrial safety. For instance, the NEC mandates that circuit breakers should have an interruption rating that corresponds to their application, with common ratings starting from 10 kA for residential to over 65 kA for heavy industrial use. Failing to adhere to these standards can lead to equipment damage and increase the risk of electrical fires, underscoring the importance of meeting these regulatory requirements.

When using thermal magnetic circuit breakers, consider these practical tips for better application. First, always verify the compatibility of the breaker with the electrical load and circuit type. For example, in settings with frequently fluctuating loads, opt for a circuit breaker with adjustable trip settings. Additionally, conduct regular maintenance checks to ensure that the breakers are functioning correctly; a study by the Electrical Safety Foundation International (ESFI) revealed that nearly 80% of electrical fires are preventable with proper equipment maintenance and adherence to safety standards. Lastly, document all testing and maintenance activities, as this not only complies with regulations but also helps in identifying performance trends over time.

Exploring the Performance of Thermal Magnetic Circuit Breakers

This chart illustrates key performance features of thermal magnetic circuit breakers, highlighting their interrupting capacity, trip reaction time, temperature rating, and number of poles. These metrics are crucial for understanding the effectiveness and safety compliance of circuit breakers in various applications.

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500